Proposal for a 100,000 Mt/day Seawater Desalination Plant in Indonesia

Geodyn Solutions proposes a 100,000 Mt/day (100,000 m³/day) seawater desalination plant in North Jakarta, Indonesia, to address freshwater shortages. Using proprietary GeoRO™, Ge- oGraphene™, GeoSolar™, GeoHybrid™, GeoForward™, and GeoZero™ technologies, the plant ensures efficiency and sustainability. GeoZero™ recovers salts for fertilizers and commodi- ties, generating $1M/year net profit. With 0% government loans, World Bank grants, and tax incentives, it achieves a 10-year ROI of 17.86 %, creates 860–1,160 jobs, and aligns with Indone- sia’s water security goals.

1 Project Overview

- Objective: Deliver 100,000 m³/day potable water for urban, industrial, and agricultural

- Location: North Jakarta (solar potential: 5.0 kW h m−2 d−1 to 5.5 kW h m−2 d−1).

- Technology: GeoRO™, GeoGraphene™, GeoSolar™, GeoHybrid™, GeoForward™, GeoZero™.

- Capacity: 100,000 m³/day, expandable to 150,000 m³/day.

- Timeline: 4 years (2025–2029): 1 year feasibility/permitting, 2 years construction, 1 year

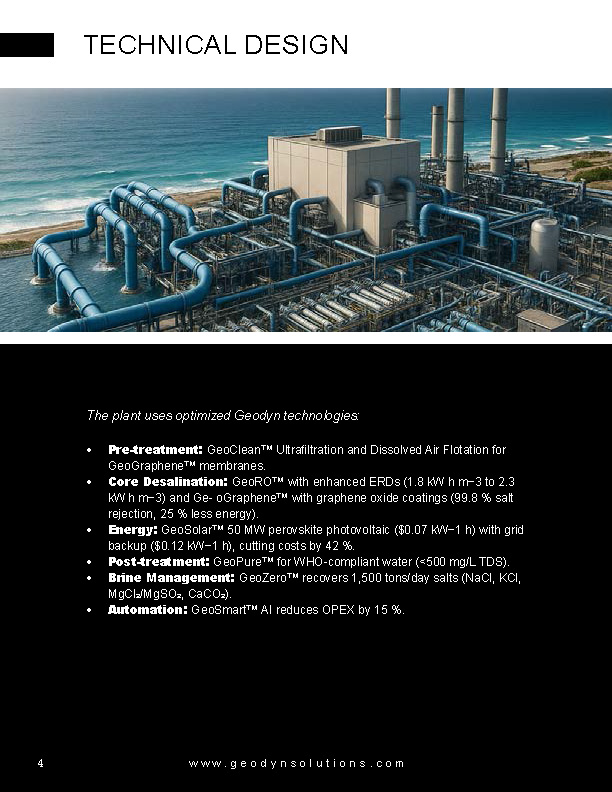

2 Technical Design

The plant uses Geodyn’s proprietary technologies:

- Pre-treatment: GeoClean™ Ultrafiltration and Dissolved Air Flotation minimize fouling for GeoGraphene™ membr

- Core Desalination: GeoRO™ with ERDs (2.0 kW h m−3 to 2.5 kW h m−3) and GeoGraphene™ Membranes (99.8 % salt rejection, 20 % less energy).

- Energy: GeoSolar™ 30 MW photovoltaic ($0.08 kW−1 h) with grid backup ($0.12 kW−1 h), cut- ting costs by 30 %.

- Post-treatment: GeoPure™ Remineralization for WHO-compliant water (<500 mg/L TDS).

- Brine Management: GeoZero™ recovers 5–10 tons/day salts (NaCl, KCl, MgCl₂/MgSO₄, CaCO₃).

- Automation: GeoSmart™ AI reduces OPEX by 15 %.

3 Technologies for Profitability

Geodyn’s technologies enhance ROI:

- GeoGraphene™: Cuts energy use by 20 % to 30 % (∼2 kW h m−3), extends membrane life to 8–10

- GeoSolar™: Reduces energy costs to $0.08 kW−1

- GeoForward™: Lowers GeoZero™ energy costs by 10 % to 15 %.

- GeoSmart™: Cuts maintenance costs by 15 %.

- GeoZero™: Generates $1 net profit from salts, offsetting OPEX by 6 %.

4 Most Efficient Technologies for ROI

- GeoRO™ with ERDs: 2.0 kW h m−3 to 2.5 kW h m−3, $0.26 m−3 to 0.80 m−3,

- GeoHybrid™ RO-MED: Uses waste heat, cutting energy costs by 20 %.

- GeoSolar™: Reduces energy costs by 30 % to 40 %.

- GeoZero™: Adds brine byproduct

5 Brine Valorization: Fertilizer and Commodity Production

GeoZero™ recovers 5–10 tons/day of salts from 1.5–2 million m³/year brine (40–50% water recovery):

• Fertilizers:

- KCl ($300 to 400 ): Potash for agriculture (7.5 demand).

- MgSO₄ ($200 to 300 ): For magnesium-deficient

- CaCO₃ ($100 to 150 ): Soil

• Commodities:

- NaCl ($50 to 100 ): Industrial use (4 demand).

- MgCl₂ ($200 to 300 ): Cement, dust

- Process: Nanofiltration and electrochemical separation yield 70 % NaCl, 15 % KCl, 10 % MgCl₂/MgSO₄,

5 % CaCO₃. Crystallization uses GeoHybrid™/GeoSolar™ waste heat.

- Output: 1,825–3,650 tons/year, revenue $0.219 to 0.538 (midpoint $0.379M). Net profit: $1 after $2.65 costs ($0.076 m−3).

- Feasibility: Indonesia’s agriculture (13 % GDP) and industrial markets ensure demand, with ASEAN export

- Environmental Benefits: Reduces brine discharge by 50 %, supports sustainable agricul-

6 Feasibility Studies

- Water Demand: 20 % freshwater shortfall by 2035, Jakarta subsidence (10 cm/year) neces- sitates

- Site Selection: North Jakarta minimizes distribution EIAs assess marine impacts.

- Technical Feasibility: GeoRO™/GeoGraphene™ match Singapore’s Jurong Island (3.5 kW h m−3, targeting 1.5 kW h m−3).

- Regulatory Framework: Requires EIAs, brine monitoring, community

7 Capital Expenditure (CAPEX)

Total CAPEX: $180, reduced to $171 with tax incentives:

- Direct Costs (70 %, $126): GeoRO™/GeoGraphene™ ($60), GeoSolar™ 30 MW ($35), piping ($20), site ($11).

- Indirect Costs (10 %, $18): Engineering ($8), permitting/EIAs ($7), financing/legal ($3).

- Contingency (20 %): $36.

- Tax Incentives: $9 via BKPM

8 Operational Expenditure (OPEX)

Annual OPEX: $19.08 ($0.55 m−3), 95 % availability (34,675,000 m³/year):

- Energy (34 %): $6.57 (2.5 kW h m−3, $0.08 kW−1 h).

- Labor (4 %): $0.83.

- GeoGraphene™ Replacement (4 %): $0.82 (8 years).

- Maintenance (6 %): $1.

- Consumables (3 %): $0.

- GeoZero™ Processing (14 %): $2.65 ($0.076 m−3).

- Fixed Costs (35 %): $6.57.

9 Employment Costs

- Construction (2 years): 600–800 jobs, $8 : 200 engineers ($25.000 , $5), 400 workers ($6.000 ,

$2.4), 100 managers ($30.000 , $0.6).

- Operational: 60 jobs, $0.83 (3 % escalation): 20 technicians ($20.000 , $0.4), 10 engineers ($25.000 , $0.25), 30 support ($6.000 , $0.18).

- Indirect Jobs: 200–300 in supply chains/services.

- Training: $0.1 with

10 Water Pricing

- Price: $0.75 m−3, competitive ($0.60 m−3 to 1.20 m−3), 36 % margin over OPEX ($0.55 m−3). Subsidies may lower to $0.50 m−3.

- Revenue: 34,675,000 m³/year × $0.75 m−3 = $26.01 , plus $1 GeoZero™, totaling $27.01 .

11 Government Support and Incentives

- 0% Loan: Bappenas 0% interest loan for 50 % CAPEX ($90, 30 years).

- World Bank: Grants of $10 to 30 for sustainable water

- Tax Incentives: BKPM tax holidays/import duty exemptions, $9 CAPEX

- Impact: Reduces CAPEX to $171, boosts R

12 Return on Investment (ROI)

• Assumptions:

- Revenue: $27.01

– OPEX: $19.08

- CAPEX repayment: $5.7 (30-year, 0% for $90, 5 % for $81, 5-year interest-only)

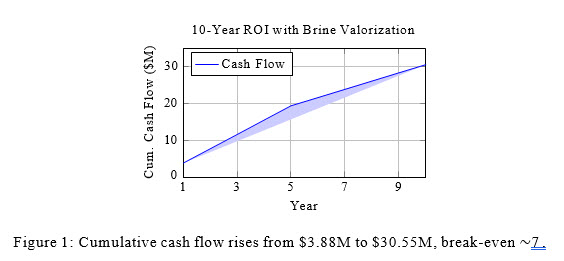

– Net Cash Flow: $3.88 (Years 1–5), $2.23 (Years 6–10)

– Total 10-Year Cash Flow: ($3.88 × 5) + ($2.23 × 5) = $30.55

– ROI: ($30.55 / $171) × 100 % = 17.86 %

- Break-even: ∼7

13 10-Year Return Table

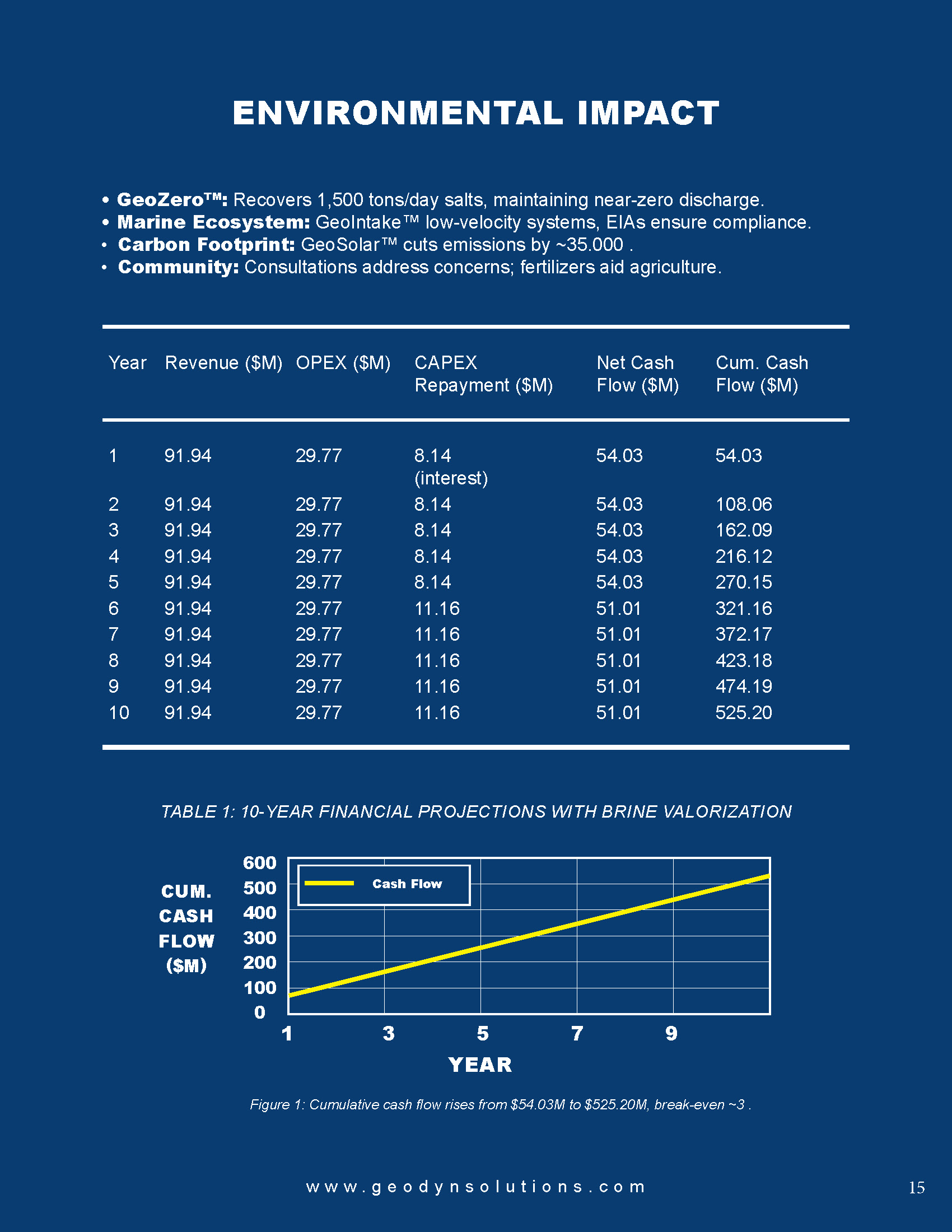

Table 1: 10-Year Financial Projections with Brine Valorization

10-Year ROI with Brine Valorization

14 10-Year ROI Graph

- Environmental Impact

- GeoZero™: Recovers 5–10 tons/day salts, reducing discharge by 50 %.

- Marine Ecosystem: GeoIntake™ low-velocity systems, EIAs ensure

- Carbon Footprint: GeoSolar™ cuts emissions by ∼35.000 .

- Community: Consultations address noise, visual concerns; fertilizers aid

16 Economic and Social Benefits

- Water Security: Serves 500,000–1,000,000 residents/industries.

- Job Creation: 600–800 construction, 60 permanent, 200–300 indirect

- Economic Impact: Boosts GDP by 0.5 % to 1 %.

17 Risks and Mitigation

- Cost Overruns: 20 % contingency ($36).

- Environmental: EIAs, GeoZero™ ensure

- Energy Costs: GeoSolar™ with grid

- Market Saturation: Diversified products, ASEAN

- Social Resistance: Community benefits (training, infrastructure).

18 Financing Strategy

- PPP Model: Partners with government, World Bank, Asian Development

- Loan: 50 % ($90) 0% via Bappenas, 50 % ($81) 5 %, 30-year, 5-year interest-only.

- Grants/Incentives: World Bank grants ($10 to 30), BKPM tax exemptions ($9).

- Revenue: $0.75 m−3 + $1 GeoZero™.

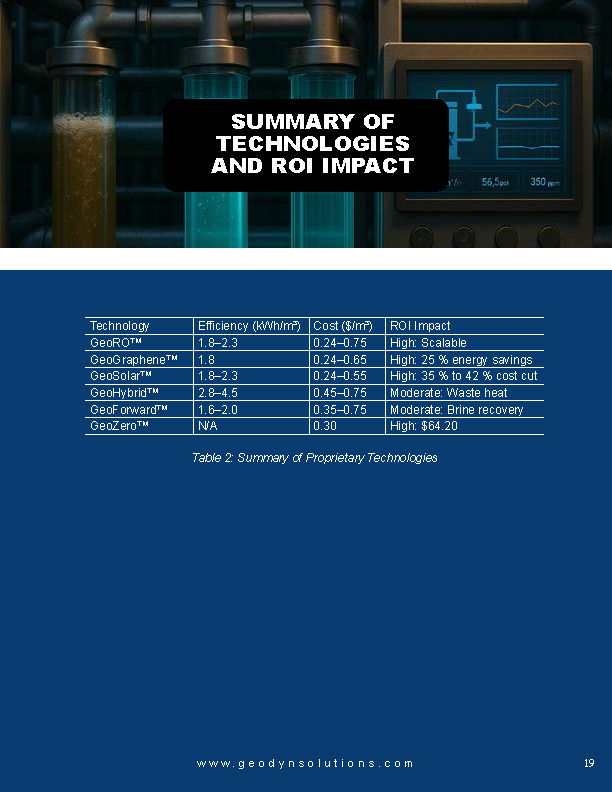

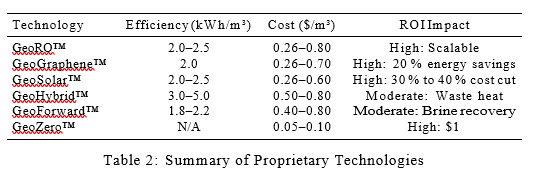

19 Summary of Technologies and ROI Impact

Technology | Efficiency (kWh/m³) | Cost ($/m³) | ROI Impact |

GeoRO™ | 2.0–2.5 | 0.26–0.80 | High: Scalable |

GeoGraphene™ GeoSolar™ GeoHybrid™ | 2.0 2.0–2.5 3.0–5.0 | 0.26–0.70 0.26–0.60 0.50–0.80 | High: 20 % energy savings High: 30 % to 40 % cost cut Moderate: Waste heat |

GeoForward™ | 1.8–2.2 | 0.40–0.80 | Moderate: Brine recovery |

GeoZero™ | N/A | 0.05–0.10 | High: $1 |

Table 2: Summary of Proprietary Technologies

20 Conclusion

Geodyn Solutions’ 100,000 Mt/day desalination plant, powered by GeoRO™, GeoGraphene™, GeoSolar™, and GeoZero™, delivers water at $0.75 m−3, achieving a 17.86 % ROI over 10 years, break-even by Year 7, with 0% loans, World Bank grants, and tax incentives. GeoZero™ gener- ates $1 from fertilizers (KCl, MgSO₄, CaCO₃) and commodities (NaCl, MgCl₂), creating 860–1,160 jobs. Initiate EIAs by Q4 2025 for 2026 construction.

21 Contact

Geodyn Solutions

Email:info@geodynsolutions.com