Geodyn Solutions: Revised Multi-Species Feed Manufacturing Facility Proposal for the Dominican Republic

Geodyn Solutions proposes an advanced multi-species feed manufacturing facility in the Dominican Republic to produce 250,000 tons of premium feed annually for shrimp, fish (tilapia), pork, and poultry, targeting export markets in North America, South America, and the Caribbean. This $100 million project (including 20% contingency) builds on the prior proposal (artifact_id: 3e9377e5-a516-4ddf-bce0-ed0bb04c6941), scaling production and enhancing infrastructure with a larger capital expenditure. The facility leverages nutrient-balanced formulations with probiotics, prebiotics, and sustainable ingredients—black soldier fly (BSF) larvae, silkworm pupae, algae (Spirulina, Schizochytrium sp., Chlorella vulgaris), soybean meal, fermented cassava meal, moringa leaf powder, and yeast hydrolysate. Located near Samaná Peninsula, it capitalizes on the Dominican Republic’s climate, resources, and port access to generate $375 million in annual export revenue. With a projected ROI of 128%, 1,200 jobs, and robust environmental stewardship, the project supports the $50 million tilapia and shrimp farm (artifact_id: 756c712f-8137-4b35-aa34-862f0af7c8a6) and drives economic growth in the Dominican Republic.

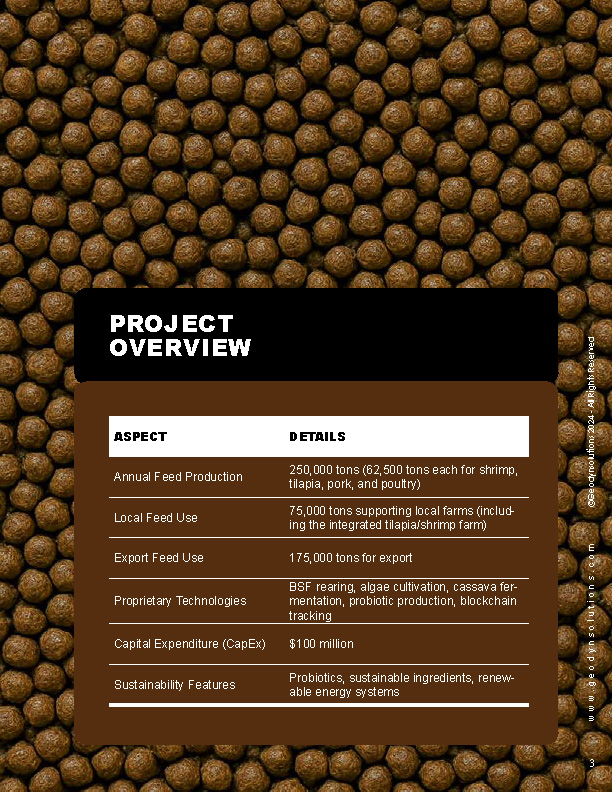

Project Overview

The facility will produce 250,000 tons of feed annually (62,500 tons each for shrimp, tilapia, pork, and poultry), with 75,000 tons supporting local farms (including the integrated tilapia/shrimp farm) and 175,000 tons for export. It integrates proprietary technologies for BSF rearing, algae cultivation, cassava fermentation, probiotic production, and blockchain tracking, ensuring cost efficiency, sustainability, and global market competitiveness. The increased $100 million CapEx enables expanded production capacity, advanced automation, and renewable energy systems, optimizing ROI and export potential.

Need for Multi-Species Feed

- Regional Demand:

- Aquaculture: North America imports 80% of its aquaculture feed; South America’s shrimp and tilapia sectors grow at 6% annually. The Caribbean relies on $500 million in feed imports yearly.

- Livestock: The Dominican Republic’s pork (100,000 tons/year) and poultry (300,000 tons/year) industries import $200 million in feed annually. Regional demand exceeds 6 million tons/year.

- Sustainability Gap: Conventional feeds depend on fishmeal and soy, straining ecosystems. Sustainable, probiotic-enhanced feeds command 10-20% price premiums in export markets.

- Local Challenges: Feed costs (30-50% of farm OpEx) hinder local farm profitability. Domestic production reduces costs and stabilizes supply.

- Export Potential: DR-CAFTA and proximity to the USA, Brazil, and Mexico enable low-tariff exports via efficient ports (Puerto Plata, Santo Domingo).

Feed Formulations

The formulations are tailored to each species, incorporating advanced ingredients from the prior proposal, optimized for nutrition, FCR, and export appeal.

- Tilapia Feed(35% protein, 8% fat, FCR ~1.14):

- 25% BSF larvae ($2,000/ton)

- 20% silkworm pupae ($2,500/ton)

- 12% Spirulina ($3,000/ton)

- 5% Schizochytrium sp. ($4,000/ton)

- 5% Chlorella vulgaris ($3,500/ton)

- 10% fermented cassava meal ($300/ton)

- 3% moringa leaf powder ($1,500/ton)

- 10% soybean meal ($500/ton)

- 2% yeast hydrolysate ($1,000/ton)

- 3% probiotics/prebiotics ($70/ton)

- 2% vitamins/minerals

- Cost per Ton: $1,400

- Shrimp Feed(40% protein, 10% fat, FCR ~1.14):

- 20% BSF larvae

- 15% silkworm pupae

- 12% Spirulina

- 10% Schizochytrium sp.

- 5% Chlorella vulgaris

- 8% fermented cassava meal

- 2% moringa leaf powder

- 12% soybean meal

- 3% yeast hydrolysate

- 3% probiotics/prebiotics

- 2% vitamins/minerals

- Cost per Ton: $1,650

- Pork Feed(18% protein, 6% fat, FCR ~2.5):

- 15% BSF larvae

- 10% silkworm pupae

- 5% Spirulina

- 2% Chlorella vulgaris

- 20% fermented cassava meal

- 2% moringa leaf powder

- 35% soybean meal

- 2% yeast hydrolysate

- 2% probiotics/prebiotics

- 2% vitamins/minerals

- Cost per Ton: $900

- Poultry Feed(22% protein, 7% fat, FCR ~1.8):

- 20% BSF larvae

- 10% silkworm pupae

- 5% Spirulina

- 3% Chlorella vulgaris

- 15% fermented cassava meal

- 2% moringa leaf powder

- 30% soybean meal

- 3% yeast hydrolysate

- 2% probiotics/prebiotics

- 2% vitamins/minerals

- Cost per Ton: $1,100

Proprietary Technologies

- BSF Rearing Modules: Process 5,000 tons/year of organic waste into 2,500 tons of larvae, co-developed with EntoFarm Solutions.

- Algae Bioreactors: 20-hectare hybrid system for Spirulina, Schizochytrium, and Chlorella, using wastewater, co-developed with AlgaeTech.

- Cassava Fermentation Units: Bioreactors ferment 12,500 tons/year of cassava, enhancing digestibility.

- Feed Extrusion: Bühler Group extruders with probiotic coating, achieving low FCR.

- Microbial Bioreactors: Produce Bacillus subtilis, Lactobacillus plantarum, Saccharomyces cerevisiae, and water microbiology cultures (Nitrosomonas, Nitrobacter), co-developed with AquaBioTech Group.

- Renewable Energy Systems: 2 MW solar array and battery storage offset 60% of energy needs.

- Blockchain Tracking: IBM platform tracks ingredients and sustainability metrics, ensuring ASC, BAP, and GMP+ compliance.

- Automation Systems: IoT-enabled sensors and AI optimize production, reducing labor by 50%.

Economic Feasibility

The $100 million CapEx supports a high-capacity, automated facility with enhanced ROI.

- Capital Expenditure (CapEx):

- Land and site preparation: $9 million

- Feed manufacturing plant (extruders, grinders, mixers): $28 million

- BSF rearing modules: $14 million

- Algae bioreactors and ponds: $18 million

- Silkworm processing and storage: $7 million

- Microbial bioreactors and dosing systems: $7 million

- Cassava fermentation units: $3 million

- Renewable energy systems (2 MW solar): $4 million

- Blockchain and IoT systems: $5 million

- Training, permits, miscellaneous: $3 million

- Contingency (20%): $16 million

- Total CapEx: $100 million

- Operational Expenditure (OpEx):

- Raw materials: $175 million/year

- Probiotics/prebiotics/microbial cultures: $5 million/year

- Labor: $5 million/year (200 staff, automation reduces headcount)

- Energy: $2.5 million/year (solar offsets 60%)

- Maintenance and blockchain: $3.5 million/year

- Total OpEx: $191 million/year

- Revenue Projections:

- Production: 250,000 tons (62,500 tons each for tilapia, shrimp, pork, poultry)

- Selling price: $2,000/ton (tilapia), $2,400/ton (shrimp), $1,200/ton (pork), $1,400/ton (poultry)

- Export revenue: 175,000 tons (43,750 tons each) = $87.5M (tilapia) + $105M (shrimp) + $52.5M (pork) + $61.25M (poultry) = $306.25M

- Local revenue: 75,000 tons = $37.5M (tilapia) + $45M (shrimp) + $22.5M (pork) + $26.25M (poultry) = $131.25M

- Internal savings: 25,000 tons for tilapia/shrimp farm saves $6M/year

- Total Revenue: $443.5 million/year

- Return on Investment (ROI):

- Net profit: $443.5M – $191M = $252.5 million/year

- ROI: ($252.5M / $100M) × 100 = 5% annually

- Payback period: ~0.40 years

- Economic Benefits for the Dominican Republic:

- Job Creation: 200 direct jobs (operators, technicians, microbiologists, IT) and 1,000 indirect jobs (cassava farming, moringa cultivation, logistics, waste collection).

- Export Revenue: $306.25 million/year, boosting foreign exchange reserves.

- Local Economy: Replaces $200M/year in feed imports, stimulates agriculture, and upgrades port infrastructure.

- Food Security: Enhances local pork, poultry, and aquaculture production by 20% with affordable, high-quality feed.

- Farm Synergy: Saves $6M/year in feed costs for the tilapia/shrimp farm.

Environmental Stewardship

- Waste Reduction: BSF converts 5,000 tons/year of organic waste, reducing landfill use by 85%.

- Water Treatment: Algae and microbial bioreactors treat 2.5 million gallons/year of wastewater, supporting zero-discharge systems.

- Low Carbon Footprint: 2 MW solar array and waste-based inputs cut emissions by 65% vs. conventional feeds.

- Sustainable Sourcing: Eliminates fishmeal/fish oil, preserving marine ecosystems. Cassava, moringa, and yeast hydrolysate utilize local byproducts.

- Healthier Animals: Probiotics and yeast hydrolysate reduce antibiotic use by 70-80%, minimizing environmental contamination.

- Transparency: Blockchain verifies sustainability metrics, meeting ASC, BAP, and GMP+ standards.

Positive Economic Impact on the Dominican Republic

- Agricultural Development: Stimulates cassava (60,000 tons/year), moringa (2,500 tons/year), and soybean cultivation, creating rural jobs.

- Trade Balance: Replaces $200M/year in feed imports and generates $306.25M/year in exports, improving trade surplus.

- Infrastructure Growth: Enhances port and logistics networks, supporting DR-CAFTA trade.

- Innovation Hub: Establishes the Dominican Republic as a leader in sustainable feed technology, attracting global investment.

- Community Benefits: Training programs with UASD and INTEC reduce unemployment by 1.5-2% in Samaná, fostering a skilled workforce.

Export Strategy

- Target Markets: USA (40%), Brazil (20%), Mexico (15%), Caribbean (15%), Central America (10%).

- Competitive Advantage: Probiotic-enhanced, nutrient-dense, blockchain-tracked feed meets global standards, commanding premium prices.

- Logistics: DR-CAFTA ensures low tariffs; ports facilitate efficient shipping.

- Marketing: Highlight sustainability, moringa minerals, and probiotic benefits via blockchain app, targeting eco-conscious buyers.

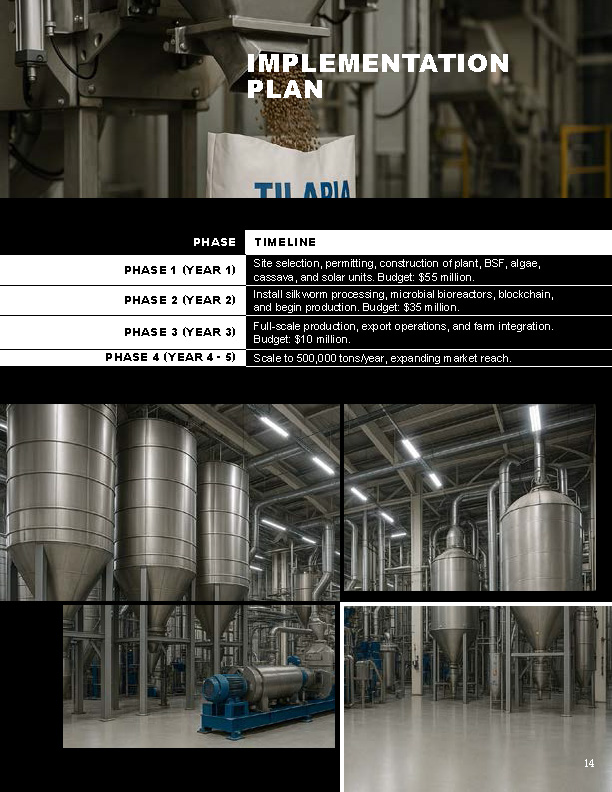

Implementation Plan

- Phase 1 (Year 1): Site selection, permitting, construction of plant, BSF, algae, cassava, and solar units. Budget: $55 million.

- Phase 2 (Year 2): Install silkworm processing, microbial bioreactors, blockchain, and begin production. Budget: $35 million.

- Phase 3 (Year 3): Full-scale production, export operations, and farm integration. Budget: $10 million.

- Phase 4 (Years 4-5): Scale to 500,000 tons/year, expanding market reach.

Risks and Mitigation

- Risk: High CapEx. Mitigation: Phased implementation, grants (FAO, World Bank), partner funding.

- Risk: Export competition. Mitigation: Premium pricing for sustainable feed.

- Risk: Raw material supply. Mitigation: Diversify cassava, moringa, and soybean sources; secure waste contracts.

- Risk: Energy costs. Mitigation: 2 MW solar array and battery storage.

Conclusion

Geodyn Solutions’ $100 million multi-species feed facility leverages advanced formulations and technologies to produce 250,000 tons of sustainable feed for shrimp, tilapia, pork, and poultry. With a 252.5% ROI, 1,200 jobs, $306.25 million in export revenue, and robust environmental stewardship, it transforms the Dominican Republic into a global feed production hub, driving economic growth, food security, and sustainability.