Proposal for Large-Scale Organic Coffee Farming and High-Value Processing in the Dominican Republic

Executive Summary

Geodyn Solutions proposes developing a 10,000-hectare organic coffee plantation and a state-of-the-art processing factory in the Dominican Republic to produce high-value coffee products (roasted beans, ground coffee, instant coffee, and coffee extracts) for export to the United States and Europe. Utilizing advanced agricultural technologies, biofertilizers, and sustainable agroforestry, this project will maximize yield, enhance quality, and improve nutrient profiles. The initiative will create 25,000–30,000 jobs, deliver a 15–20% return on investment (ROI), and provide significant environmental benefits, with a 20% contingency fee to mitigate risks.

Project Overview

Objectives

- Agricultural Development: Cultivate 10,000 hectares of organic coffee using advanced technologies and biofertilizers to achieve high yields and premium quality.

- Processing Facility: Build a factory to produce roasted beans, ground coffee, instant coffee, and coffee extracts for export to high-value markets.

- Economic Impact: Generate 25,000–30,000 direct and indirect jobs, including farmworkers, factory staff, and technical roles.

- Environmental Benefits: Enhance biodiversity, sequester carbon, and improve soil health through organic agroforestry and biofertilizer use.

- Financial Viability: Achieve a projected ROI of 15–20% annually after Year 6, with a payback period of 8–9 years.

Location

The project will span multiple provinces (Barahona, Bahoruco, and San Juan), selected for their high-altitude volcanic soils, ideal microclimates (1,000–1,500m elevation), and proximity to export ports. Sites will comply with the European Union Deforestation Regulation (EUDR) and avoid protected areas.

Agricultural Plan

Farm Design

- Size: 10,000 hectares, divided into 200 plots of 50 hectares for scalable management.

- Agroforestry Model: Coffee shrubs will be intercropped with shade trees (e.g., Inga, banana, cedar) and high-value crops (e.g., cardamom, vanilla) to diversify income, enhance biodiversity, and improve soil health.

- Coffee Varieties: Premium Arabica varieties (Typica, Bourbon, Caturra), sourced from certified nurseries, optimized for specialty coffee markets.

- Organic Certification: Adherence to USDA Organic, EU Organic, Fairtrade, and Rainforest Alliance standards to access high-value markets.

Advanced Agricultural Technologies

- Biofertilizers: Microbial biofertilizers (e.g., Azospirillum, phosphate-solubilizing bacteria) to enhance nutrient uptake, increase yields by 20–30%, and improve coffee bean nutrient profiles (e.g., higher antioxidant content).

- Precision Agriculture: Drones for crop monitoring, soil sensors for nutrient analysis, and AI-driven models to optimize planting and harvesting schedules.

- Irrigation: Solar-powered drip irrigation with IoT integration to reduce water use by 40% and maintain optimal soil moisture.

- Pest Management: Integrated pest management (IPM) with biopesticides and resistant varieties to control coffee leaf rust and berry borer, minimizing chemical use.

- Automation: Robotic pruning and selective harvesting systems to improve efficiency and reduce labor costs by 15%.

Cultivation Practices

- Planting: 4,000 coffee shrubs per hectare, with 100 shade trees per hectare. Planting will occur in phases over Years 1–3, with first harvests in Year 4.

- Yield Projections: Average yield of 1,000–1,200 kg/ha of green coffee beans by Year 6, increasing to 1,500 kg/ha by Year 10 with biofertilizer and technology enhancements.

- Sustainability: Biofertilizers and organic practices reduce synthetic inputs, while agroforestry sequesters 10–15 tons CO2/ha annually.

- Training: 5,000 farmers trained in advanced techniques, biofertilizer application, and technology use, building on CODOCAFE’s success in improving yields.

Processing Factory

Facility Design

- Location: Centralized facility near Barahona, with proximity to farms and the Port of Barahona for efficient logistics.

- Capacity: Process 15,000 metric tons of green coffee beans annually, producing 3,000 tons of roasted beans, 4,500 tons of ground coffee, 3,000 tons of instant coffee, and 1,500 tons of coffee extracts.

- Equipment: Advanced machinery (e.g., automated roasters, grinders, spray-drying units) from Probat and GEA, with blockchain-enabled traceability systems.

- Certifications: Compliance with FDA, EU Organic, Fairtrade, and EUDR standards, ensuring market access and consumer trust.

Production Process

- Washing and Drying: Cherries processed using wet (washed) methods, then dried to 10–12% moisture in solar-assisted dryers for optimal flavor.

- Processing: Beans hulled, roasted, and ground or processed into instant coffee and extracts. Roasted beans offered in light, medium, and dark profiles for specialty markets.

- Packaging: Eco-friendly, biodegradable packaging with QR codes linking to farm traceability data, appealing to premium consumers.

- Quality Enhancement: Biofertilizers increase bean chlorogenic acid and caffeine content, enhancing flavor and health benefits for high-value products.

Export Markets

- Target Markets: United States (specialty coffee retailers, cafes) and Europe (Germany, Italy, Netherlands), where organic coffee demand grows 6–8% annually.

- Pricing: Organic green coffee at $4,000–$5,000/ton, roasted beans at $8,000–$10,000/ton, ground coffee at $9,000–$11,000/ton, instant coffee at $12,000–$14,000/ton, and extracts at $15,000–$18,000/ton.

- Logistics: Partner with exporters like Belarmino Coffee and logistics firms like Maersk to streamline shipping to New York and Rotterdam.

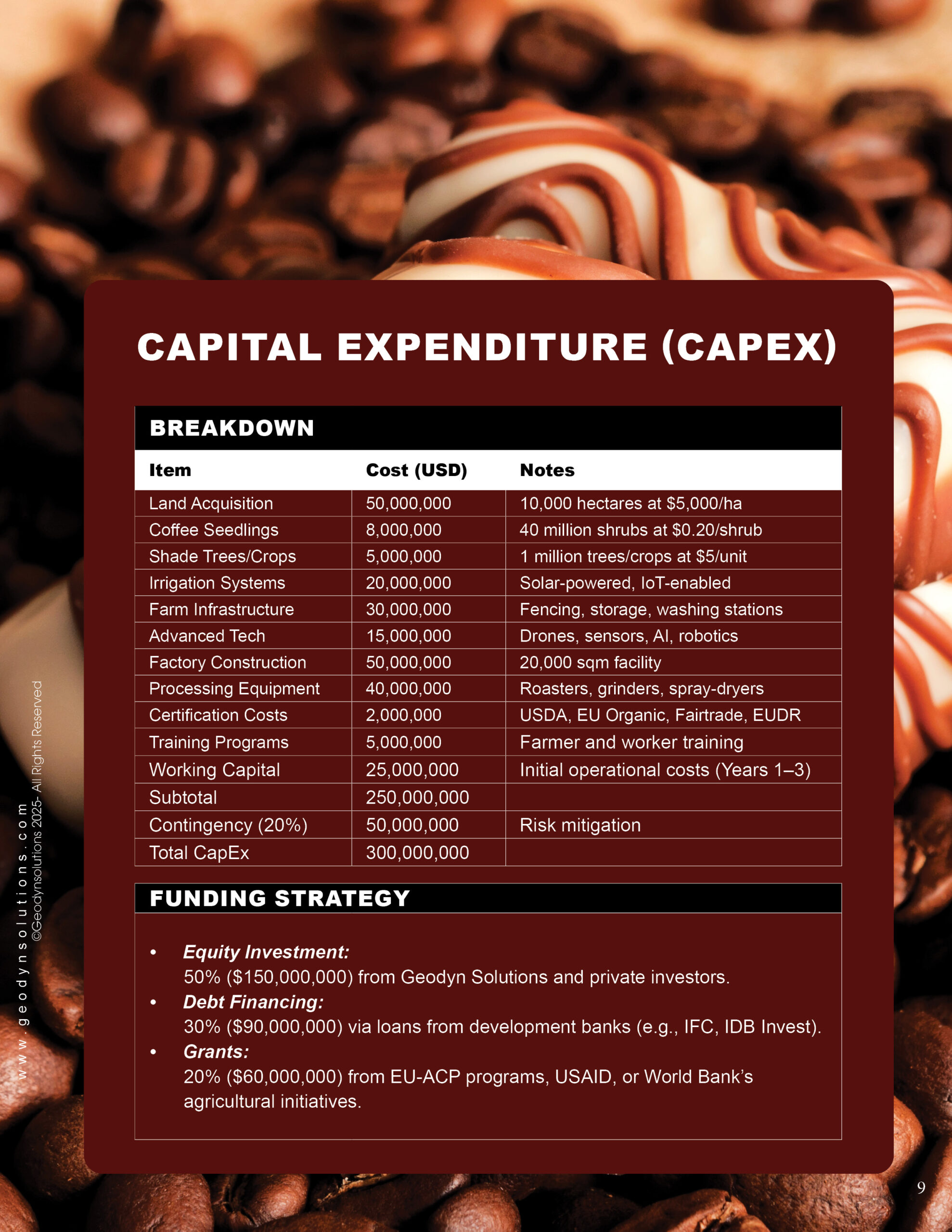

Capital Expenditure (CapEx)

Breakdown

Item | Cost (USD) | Notes |

Land Acquisition | 50,000,000 | 10,000 hectares at $5,000/ha |

Coffee Seedlings | 8,000,000 | 40 million shrubs at $0.20/shrub |

Shade Trees/Crops | 5,000,000 | 1 million trees/crops at $5/unit |

Irrigation Systems | 20,000,000 | Solar-powered, IoT-enabled |

Farm Infrastructure | 30,000,000 | Fencing, storage, washing stations |

Advanced Tech | 15,000,000 | Drones, sensors, AI, robotics |

Factory Construction | 50,000,000 | 20,000 sqm facility |

Processing Equipment | 40,000,000 | Roasters, grinders, spray-dryers |

Certification Costs | 2,000,000 | USDA, EU Organic, Fairtrade, EUDR |

Training Programs | 5,000,000 | Farmer and worker training |

Working Capital | 25,000,000 | Initial operational costs (Years 1–3) |

Subtotal | 250,000,000 | |

Contingency (20%) | 50,000,000 | Risk mitigation |

Total CapEx | 300,000,000 |

Funding Strategy

- Equity Investment: 50% ($150,000,000) from Geodyn Solutions and private investors.

- Debt Financing: 30% ($90,000,000) via loans from development banks (e.g., IFC, IDB Invest).

- Grants: 20% ($60,000,000) from EU-ACP programs, USAID, or World Bank’s agricultural initiatives.

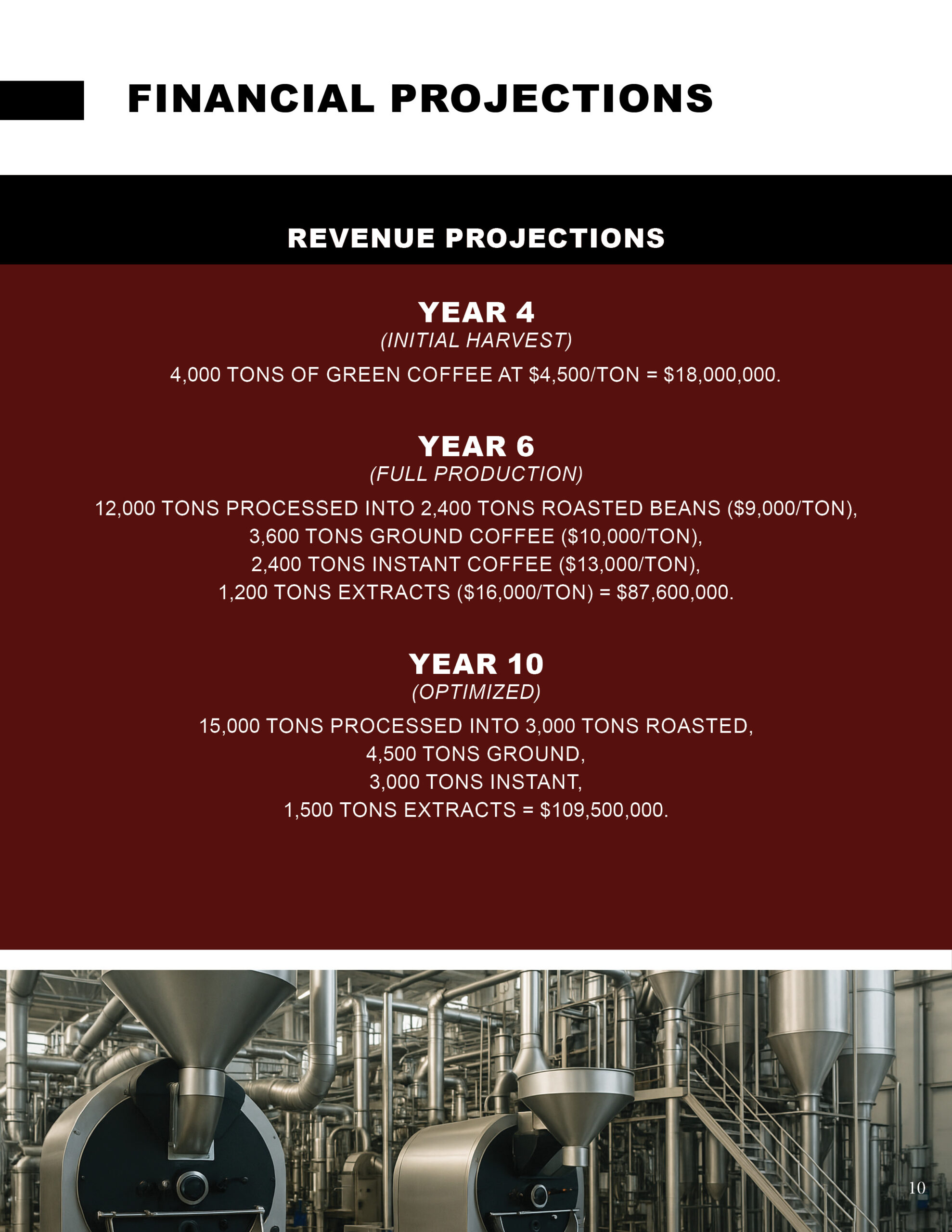

Financial Projections

Revenue Projections

- Year 4 (Initial Harvest): 4,000 tons of green coffee at $4,500/ton = $18,000,000.

- Year 6 (Full Production): 12,000 tons processed into 2,400 tons roasted beans ($9,000/ton), 3,600 tons ground coffee ($10,000/ton), 2,400 tons instant coffee ($13,000/ton), 1,200 tons extracts ($16,000/ton) = $87,600,000.

- Year 10 (Optimized): 15,000 tons processed into 3,000 tons roasted, 4,500 tons ground, 3,000 tons instant, 1,500 tons extracts = $109,500,000.

Operating Expenses (Annual, Year 6)

- Labor: $50,000,000 (25,000 workers at $2,000/year average)

- Maintenance: $10,000,000

- Utilities: $5,000,000

- Packaging/Transport: $15,000,000

- Certifications: $2,000,000

- Total: $82,000,000

ROI Calculation

- Net Profit (Year 6): $87,600,000 (revenue) – $82,000,000 (OpEx) = $5,600,000.

- Net Profit (Year 10): $109,500,000 – $82,000,000 = $27,500,000.

- Cumulative Cash Flow: Positive by Year 8, with ROI of 15–20% annually by Year 10, driven by high-value products and yield improvements.

Payback Period

- Initial investment ($300,000,000) recovered by Year 8–9, assuming stable market prices and optimized yields.

Job Creation

- Farmworkers: 20,000 full-time workers for planting, maintenance, and harvesting ($1,500–$2,000/year).

- Factory Staff: 4,000 workers for processing, packaging, and quality control ($2,500–$3,500/year).

- Technical/Administrative: 1,000 roles (agronomists, engineers, export managers) at $5,000–$15,000/year.

- Total Jobs: 25,000 direct jobs, plus 5,000 indirect jobs (e.g., logistics, equipment suppliers).

- Social Impact: Prioritize local hiring, with 40% of roles for women and youth to promote inclusivity and address labor shortages.

Environmental Benefits

- Biodiversity: Agroforestry supports native species, with shade trees and intercrops creating habitats for birds and pollinators.

- Carbon Sequestration: 10,000 hectares sequester 100,000–150,000 tons CO2 annually, equivalent to offsetting emissions from 25,000 cars.

- Soil Health: Biofertilizers enhance microbial activity, improving nutrient cycling and reducing erosion by 50%.

- Water Efficiency: IoT irrigation and shade trees reduce water use by 40%, preserving local watersheds.

- Deforestation Compliance: EUDR-compliant site selection ensures no forest loss, aligning with global sustainability goals.

Risk Mitigation

- Market Risks: Diversified high-value products and long-term contracts with buyers (e.g., Starbucks, Nestlé) stabilize revenue.

- Disease: Advanced IPM and resistant varieties, supported by CODOCAFE protocols, minimize crop losses.

- Technology Failure: Redundant systems and local technician training ensure operational continuity.

- Contingency Fund: 20% ($50,000,000) allocated for unforeseen costs (e.g., climate events, equipment delays).

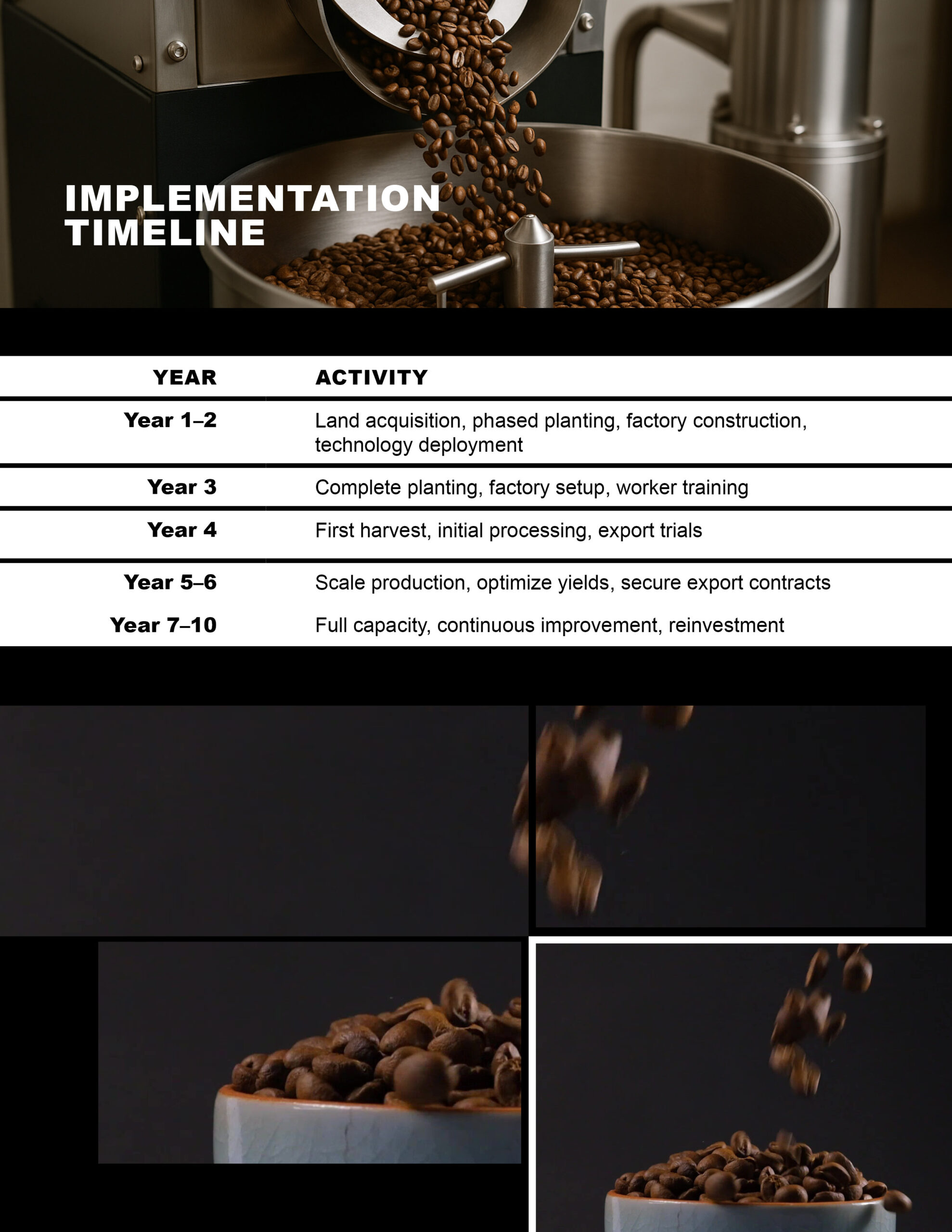

Implementation Timeline

Year | Activity |

Year 1–2 | Land acquisition, phased planting, factory construction, technology deployment |

Year 3 | Complete planting, factory setup, worker training |

Year 4 | First harvest, initial processing, export trials |

Year 5–6 | Scale production, optimize yields, secure export contracts |

Year 7–10 | Full capacity, continuous improvement, reinvestment |

Conclusion

Geodyn Solutions’ 10,000-hectare organic coffee plantation and high-value processing factory will establish the Dominican Republic as a global leader in premium, sustainable coffee products. With a $300 million investment, the project will create 25,000–30,000 jobs, achieve a 15–20% ROI by Year 10, and deliver substantial environmental benefits through advanced technologies and biofertilizers. The 20% contingency fee ensures resilience, making this a transformative venture for economic and ecological sustainability.

References

- CODOCAFE, Dominican Republic Coffee Sector.

- USDA, Organic Coffee Market Trends.

- Probat, Coffee Processing Technology.

- World Bank, Agricultural Development Programs.

- Rainforest Alliance, Sustainable Coffee Farming.