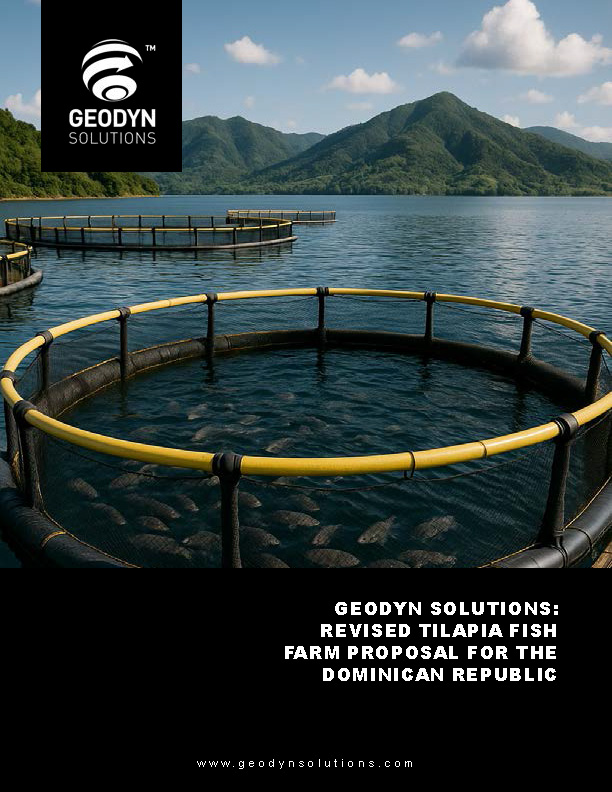

Geodyn Solutions: Revised Tilapia Fish Farm Proposal for the Dominican Republic

Executive Summary

Geodyn Solutions proposes a state-of-the-art tilapia fish farm in the Dominican Republic, leveraging proprietary technologies developed with strategic partners to achieve unmatched cost efficiency and environmental sustainability. Inspired by the Recirculating Aquaculture System (RAS) model this $50 million project (including 20% contingency) integrates advanced RAS, Biofloc Technology (BFT), Integrated Multi-Trophic Aquaculture (IMTA), automated systems, renewable energy, and blockchain-based tracking. The farm will produce 6 million pounds of tilapia annually, positioning the Dominican Republic as a leading aquaculture export hub for North and South America. The proposal emphasizes high return on investment (ROI), job creation, environmental benefits, and economic growth through a dedicated warehouse and processing center.

Project Overview

The tilapia fish farm will utilize proprietary technologies to optimize production, reduce costs, and minimize environmental impact. With a $50 million budget, the project scales up infrastructure, incorporates blockchain for supply chain transparency, and enhances sustainability. The facility will include a warehouse and processing center to support exports to North and South America, capitalizing on the Dominican Republic’s strategic location and trade advantages.

Why Tilapia?

Tilapia remains the ideal species due to:

- Global Demand: Third most farmed fish globally, with strong demand in North and South America for its affordability and mild flavor.

- Resilience: Thrives in high-density RAS, tolerates varying water conditions, and resists disease.

- Fast Growth: Reaches marketable size (1-2 pounds) in 10-12 months, enabling rapid production cycles.

- Low Feed Conversion Ratio (FCR): FCR of ~1.5 reduces feed costs compared to species like salmon.

- Sustainability: Low environmental footprint, especially with RAS and IMTA, aligns with global sustainability goals.

Proprietary Technologies with Partners

Geodyn Solutions has partnered with leading aquaculture and technology firms (e.g., Blue Ridge Aquaculture, Pentair Aquatic Eco-Systems, and IBM for blockchain) to develop proprietary technologies tailored to the Dominican Republic’s climate and market needs. These technologies, adapted from the video’s RAS model, prioritize cost efficiency and environmental friendliness:

- Proprietary Recirculating Aquaculture System (RAS):

- Description: A custom-designed RAS, co-developed with Pentair, recycles 90% of water using advanced biofiltration, solids removal, UV disinfection, and oxygenation.

- Cost Efficiency: Reduces water usage to 1% of traditional systems, lowering pumping and treatment costs by 80%.

- Environmental Benefits: Zero discharge through enhanced biofilters, protecting local waterways.

- Implementation: Modular RAS units with proprietary sensors for real-time monitoring of temperature, pH, dissolved oxygen, and ammonia (accuracy ±0.1 ppm). Each unit supports ultra-high-density production (120 kg/m³).

- Enhanced Biofloc Technology (BFT):

- Description: A proprietary BFT system, developed with Blue Ridge Aquaculture, optimizes microbial growth to consume waste and supplement feed.

- Cost Efficiency: Reduces feed costs by 30% (microbes provide 20% of protein needs) and eliminates water exchange costs.

- Environmental Benefits: Converts waste into biomass, reducing nutrient pollution and supporting a circular economy.

- Implementation: Integrated into RAS with high-capacity aeration (20 HP, 600 CFM) and proprietary diffuser grids for oxygen efficiency.

- Automated Feeding and Monitoring Systems:

- Description: AI-driven feeders and cameras, co-developed with a tech partner, deliver precise feed amounts based on fish behavior and water quality.

- Cost Efficiency: Cuts feed waste by 20% and labor costs by 30%, eliminating 24/7 staffing needs.

- Environmental Benefits: Minimizes uneaten feed, reducing organic waste in tanks.

- Implementation: IoT-enabled feeders synced with a proprietary farm management platform, providing predictive analytics for feeding and maintenance.

- Proprietary Integrated Multi-Trophic Aquaculture (IMTA):

- Description: A custom IMTA system, developed with academic partners, combines tilapia with shellfish (e.g., oysters) and seaweed (e.g., Ulva) to create a symbiotic ecosystem.

- Cost Efficiency: Diversifies revenue (seaweed for food/cosmetics, shellfish for seafood) and reduces waste treatment costs by 50%.

- Environmental Benefits: Shellfish and seaweed absorb nutrients, eliminating effluent and enhancing biodiversity.

- Implementation: Dedicated IMTA module with proprietary nutrient flow models to optimize species interactions.

- Renewable Energy and Energy Optimization:

- Description: A proprietary energy system, co-developed with a solar technology partner, uses solar panels, energy-efficient pumps, and battery storage.

- Cost Efficiency: Offsets 80% of energy costs, saving $1 million annually.

- Environmental Benefits: Reduces carbon emissions by 70% compared to grid-only systems.

- Implementation: 1 MW solar array with proprietary energy management software to prioritize renewable power usage.

- Blockchain-Based Supply Chain Tracking:

- Description: A proprietary blockchain platform, built with IBM, tracks tilapia from farm to market, recording water quality, feed inputs, and processing data.

- Cost Efficiency: Enhances marketability by ensuring transparency, commanding a 10-15% price premium for traceable, sustainable fish.

- Environmental Benefits: Promotes accountability in sustainable practices, appealing to eco-conscious consumers.

- Implementation: QR codes on packaging link to a blockchain ledger, accessible via a consumer-facing app, ensuring compliance with international standards (e.g., ASC, BAP).

- Smart Farm Management Platform:

- Description: A proprietary IoT platform integrates RAS, BFT, IMTA, and blockchain data for real-time farm management.

- Cost Efficiency: Reduces labor by 35% through automation and predictive maintenance, saving $0.5 million annually.

- Environmental Benefits: Optimizes resource use (water, feed, energy), minimizing waste.

- Implementation: Cloud-based system with mobile and desktop access, featuring AI-driven insights and blockchain integration.

Economic Feasibility

The $50 million budget (including 20% contingency) supports a scaled-up operation with enhanced technologies and infrastructure. Key financial metrics include:

- Capital Expenditure (CapEx):

- Land acquisition and site preparation: $5 million

- Proprietary RAS infrastructure (tanks, biofilters, aeration): $15 million

- Warehouse and processing center: $8 million

- Renewable energy systems (solar, batteries): $4 million

- Blockchain and IoT systems: $3 million

- Training, permits, and miscellaneous: $5 million

- Contingency (20%): $10 million

- Total CapEx: $50 million

- Operational Expenditure (OpEx):

- Feed: $3 million/year (optimized by BFT and automated feeders)

- Labor: $1.5 million/year (60 full-time staff, automation reduces headcount)

- Energy: $0.6 million/year (mitigated by solar power)

- Maintenance and blockchain operations: $1 million/year

- Total OpEx: $6.1 million/year

- Revenue Projections:

- Annual production: 6 million pounds of tilapia

- Market price: $3.5/pound (premium for blockchain-tracked, sustainable fish)

- Additional revenue from seaweed/shellfish: $1 million/year

- Total Revenue: $22 million/year

- Return on Investment (ROI):

- Net profit: $22M – $6.1M = $15.9 million/year

- ROI: ($15.9M / $50M) × 100 = 8% annually

- Payback period: ~3.2 years

- Economic Benefits for the Dominican Republic:

- Job Creation: 60 direct jobs (farm operators, processing staff, IT/blockchain specialists) and 300 indirect jobs (supply chain, logistics, retail).

- Export Revenue: $18 million/year from exports to North and South America, strengthening foreign exchange reserves.

- Local Economic Growth: Stimulates industries like feed production, equipment manufacturing, and transportation.

- Food Security: Supplies affordable, traceable protein to local markets, improving nutrition.

- Innovation Hub: Blockchain and IoT expertise positions the Dominican Republic as a leader in smart agriculture.

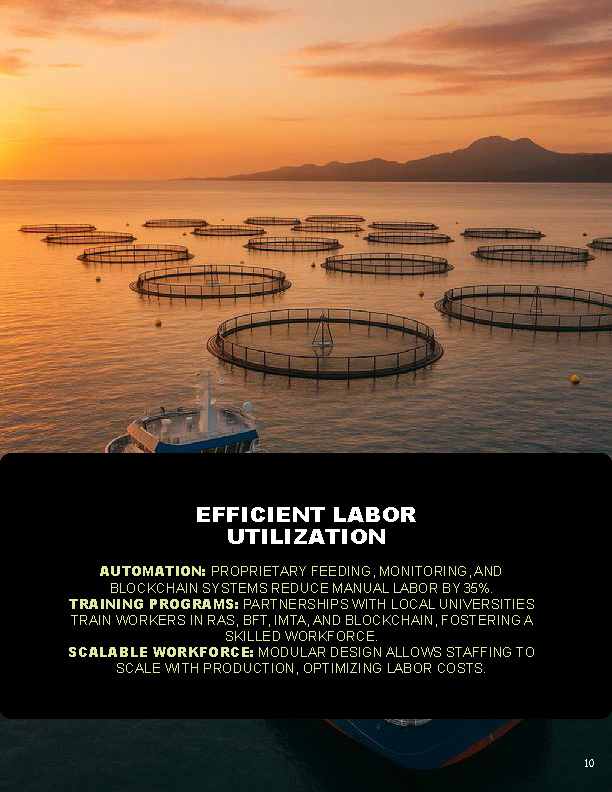

Efficient Labor Utilization

- Automation: Proprietary feeding, monitoring, and blockchain systems reduce manual labor by 35%.

- Training Programs: Partnerships with local universities train workers in RAS, BFT, IMTA, and blockchain, fostering a skilled workforce.

- Scalable Workforce: Modular design allows staffing to scale with production, optimizing labor costs.

Environmental Benefits

- Water Conservation: Proprietary RAS recycles 90% of water, using 1% of traditional systems’ requirements.

- Zero Discharge: Enhanced BFT and IMTA eliminate effluent, protecting Dominican waterways.

- Low Carbon Footprint: Solar energy and proprietary energy systems reduce emissions by 70%.

- Biodiversity Protection: IMTA and sustainable practices reduce pressure on wild fish stocks.

- Transparency: Blockchain ensures accountability in environmental claims, building consumer trust.

Dominican Republic as an Export Powerhouse

The Dominican Republic is poised to lead tilapia exports due to:

- Geographic Proximity: Close to the USA, Brazil, and Mexico, minimizing shipping costs.

- Trade Agreements: DR-CAFTA and other pacts ensure low tariffs and market access.

- Climate Advantage: Warm temperatures (80-84°F) optimize tilapia growth year-round.

- Port Infrastructure: Ports like Santo Domingo and Puerto Plata support efficient exports.

- Market Demand: North America imports 80% of its tilapia; South America’s markets are growing.

- Warehouse and Processing Center: Ensures quality (live, fresh, frozen) and blockchain-tracked traceability, meeting standards like ASC and BAP.

Implementation Plan

- Phase 1 (Year 1): Site selection, permitting, and construction of RAS and processing center. Budget: $25 million.

- Phase 2 (Year 2): Installation of proprietary BFT, IMTA, blockchain, and renewable energy systems; initial stocking. Budget: $15 million.

- Phase 3 (Year 3): Full-scale production, export operations, and IMTA scaling. Budget: $10 million.

- Phase 4 (Years 4-5): Expand to 12 million pounds annually, leveraging blockchain for premium markets.

Risks and Mitigation

- Risk: High CapEx.

- Mitigation: Phased implementation, grants (e.g., NOAA, World Bank), and partner co-funding.

- Risk: Market competition.

- Mitigation: Blockchain-tracked, sustainable tilapia commands premium pricing.

- Risk: Technical complexity.

- Mitigation: Partner expertise and robust training programs.

- Risk: Energy reliability.

- Mitigation: Proprietary solar systems and battery storage ensure uptime.

Conclusion

Geodyn Solutions’ $50 million tilapia fish farm leverages proprietary technologies to deliver cost-efficient, environmentally friendly aquaculture. By integrating advanced RAS, BFT, IMTA, automation, renewable energy, and blockchain tracking, the project achieves a 31.8% ROI, creates jobs, and positions the Dominican Republic as a tilapia export powerhouse. We invite investment and collaboration to transform the Dominican Republic into a global leader in sustainable aquaculture.