Geodyn Solution Technical Explanation-Environmental Benefits-and Carbon Management Plan

- System Operation – How the Power Plant Works

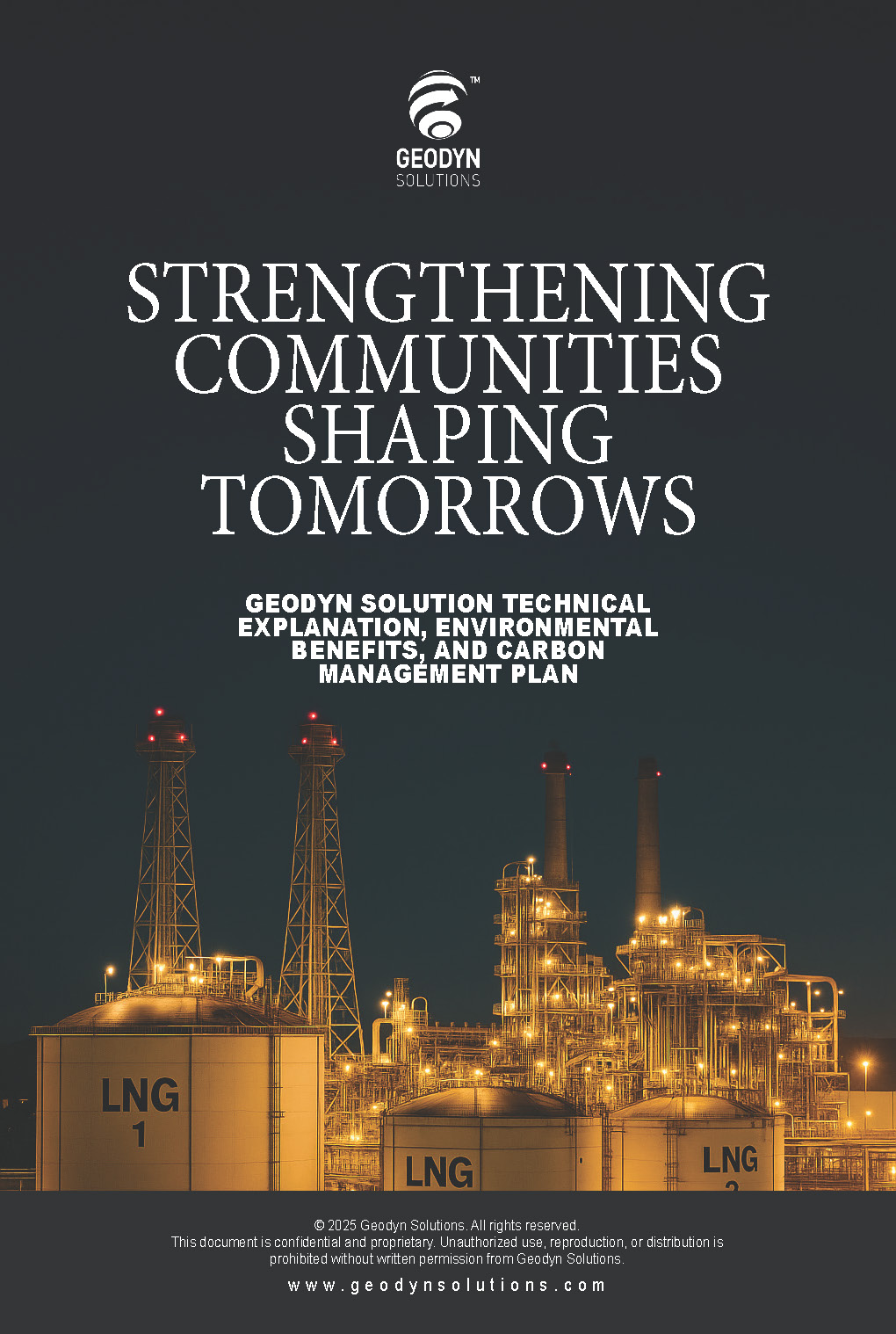

The proposed 250MW modular LNG-based power plant integrates three key technologies to maximize efficiency and flexibility:

- Primary Generation – Modular Turbines (150 MW)

- Mobile turbine-generator modules convert LNG into electrical power.

- Each unit is trailer- or container-mounted for rapid deployment and relocation.

- Advanced combustion systems ensure low emissions while maintaining high efficiency.

- Heat Recovery Steam Turbine (HRST, +75 MW)

- High-temperature exhaust gases (~500–600°C) from the turbines are captured.

- These gases pass through Heat Recovery Steam Generators (HRSGs)to produce high-pressure steam.

- The steam drives a steam turbine, adding ~75 MW of electricity without additional fuel input.

- This process raises system efficiency from ~40% (simple cycle) to ~54%.

- Organic Rankine Cycle (ORC, +25 MW)

- After HRST extraction, lower-temperature exhaust (~100–200°C) is still available.

- The ORC uses a working fluid with a lower boiling point than water (often pentane or refrigerant-like fluids).

- This fluid evaporates under waste heat, drives a turbine, and generates an additional ~25 MW.

- This final layer of energy recovery boosts overall plant efficiency to ~58%, reducing fuel requirements per MWh.

- Primary Generation – Modular Turbines (150 MW)

Together, these integrated systems achieve 250MW net capacity with a three-stage recovery cycle, maximizing output while minimizing LNG consumption.

- Environmental Benefits

- Fuel Efficiency & Reduced Emissions

- By converting waste heat into electricity, fuel consumption per MWh is reduced by 35% compared to simple-cycle turbines.

- This results in 37% lower CO₂ emissions per MWh, supporting Dominican Republic’s carbon reduction commitments.

- Air Quality Improvements

- Dry Low NOx (DLN) combustion technologyreduces NOx emissions by 80–90%, improving local air quality.

- Sulfur Oxide (SOx) emissions are effectively eliminated since LNG contains negligible sulfur.

- Particulate Matter (PM) emissions are reduced by ~88% compared to fuel oil plants.

- Water & Noise Management

- Closed-loop cooling systemsminimize freshwater withdrawals, critical in water-stressed regions.

- Acoustic enclosures and silencers ensure noise levels comply with World Bank/IFC standards.

- Land Use Optimization

- The compact modular design requires only ~15 acres, far less than coal or oil plants of comparable size.

- This minimizes habitat disruption and enables deployment on existing industrial sites.

- Fuel Efficiency & Reduced Emissions

- Carbon Management Strategy

To align with carbon neutrality pathways and global ESG requirements, Geodyn Solutions proposes an integrated Carbon Management Plan:

- Carbon Accounting & Monitoring

- Install continuous emissions monitoring systems (CEMS)to measure CO₂, NOx, and methane slip in real time.

- Data is digitally logged and integrated with AI-driven analytics for compliance and optimization.

- Carbon Reduction Measures

- High-efficiency HRST and ORC systems reduce LNG consumption per MWh.

- Explore biogenic LNG blends(bio-LNG, synthetic methane) as they become commercially available.

- Implement methane leak detection and prevention systemsacross fuel handling infrastructure.

- Carbon Offsetting & Credit Trading

- Participate in international carbon credit markets(EU ETS, CORSIA, and regional exchanges in Japan and Luxembourg).

- Credits generated from efficiency gains and avoided emissions can be tokenized and traded.

- The project can generate Certified Emission Reductions (CERs)under the UN Clean Development Mechanism.

- Circular Economy Integration

- Condensate water from HRSGs can be reclaimed and reused for auxiliary cooling and cleaning.

- Waste heat recovery reduces fuel needs, avoiding long-term LNG import dependence.

- Surplus CO₂ (captured via optional carbon capture units) can be supplied for food/beverage industryor greenhouse applications, aligning with industrial symbiosis practices.

- Long-Term Transition Plan

- The modular design allows conversion from 100% LNG to blended hydrogen-LNG firingas hydrogen infrastructure develops in the Caribbean.

- Geodyn will establish a Carbon Neutrality Roadmap (2025–2040)for phased integration of hydrogen, CCUS (Carbon Capture, Utilization, and Storage), and renewable hybridization.

- Carbon Accounting & Monitoring

- Conclusion

The 250MW modular LNG power plant combines technical innovation, environmental responsibility, and carbon management:

- High Efficiency (58%)→ Less fuel per MWh, lower CO₂ emissions.

- Environmental Safeguards→ Reduced NOx, SOx, PM, noise, and water footprint.

- Carbon Compliance→ Integrated monitoring, offset trading, and pathway to carbon neutrality.

- Future-Ready→ Adaptable to hydrogen, carbon capture, and renewable hybridization.

This ensures the Dominican Republic gains immediate energy security while aligning with Paris Agreement goals and ESG investor standards.