Geodyn 15 TPH Circular Sustainability & Revenue Initiative Proposal for The Resort

Executive Summary

The Resort has the opportunity to implement a world-class sustainability and revenue initiative centered on circular resource management. By installing the Geodyn 15 Ton-Per-Hour Total Waste Conversion System, the Resort will convert its daily organic waste streams food scraps, plant material, and biodegradable refuse into high-value agricultural commodities, specifically premium livestock feed pellets or organic fertilizer pellets.

This shift eliminates reliance on landfill disposal, reduces environmental impact, elevates ESG and green-tourism credentials, and creates a predictable, recurring revenue stream.

The Geodyn System operates with no combustion, no smoke, and no odor. Through indirect radiant heat processing, material becomes fully sterilized and market-ready in under 30 minutes, producing a stable, value-rich output suitable for sale or internal reuse. The system is permitted in California one of the most environmentally regulated jurisdictions in the world.

This initiative allows The Resort to move confidently toward a fully circular and regenerative operational model, reflecting the values of the modern luxury traveler: wellness, nature stewardship, and environmental accountability.

Strategic Value to The Resort

Impact Category | Benefit |

Environmental Leadership | Eliminates landfill dependency; significantly reduces waste footprint |

Brand Positioning | Establishes The Resort as a regional leader in sustainability-driven luxury |

Financial Performance | Creates strong recurring revenue through saleable agricultural commodities |

Guest Experience | Aligns with wellness tourism, sustainability culture, and experiential authenticity |

Regulatory Alignment | Meets and exceeds environmental standards while reducing long-term liability |

This project positions The Resort as a benchmark sustainability destination in the Caribbean.

System Overview

System Capability | Specification |

Input Capacity | 300 tons/day organic waste |

Output Capacity | 150 tons/day of finished pellets (feed or fertilizer) |

Processing Time | < 30 minutes, continuous flow |

Pathogen Elimination | 100% sterilization via indirect radiant heat |

Emissions | Zero incineration, zero odor, zero airborne emissions |

Water Circularity | Water extracted during processing is purified for irrigation and operational reuse |

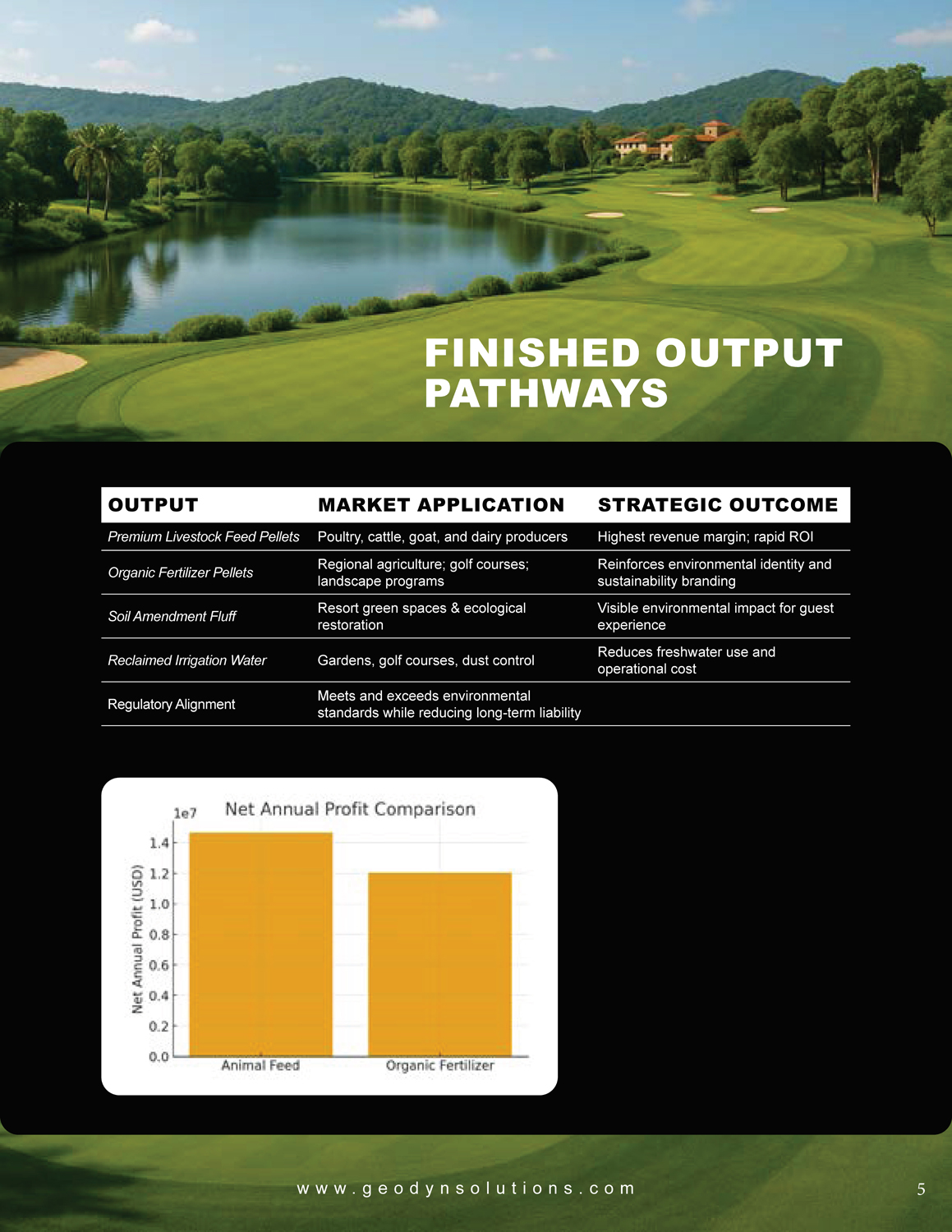

Finished Output Pathways

Output | Market Application | Strategic Outcome |

Premium Livestock Feed Pellets | Poultry, cattle, goat, and dairy producers | Highest revenue margin; rapid ROI |

Organic Fertilizer Pellets | Regional agriculture; golf courses; landscape programs | Reinforces environmental identity and sustainability branding |

Soil Amendment Fluff | Resort green spaces & ecological restoration | Visible environmental impact for guest experience |

Reclaimed Irrigation Water | Gardens, golf courses, dust control | Reduces freshwater use and operational cost |

Capital Requirement (Updated)

Item | Cost (USD) |

Geodyn 15 TPH System | $19,470,000 |

Shipping, Installation, Training & Commissioning | $1,255,000 |

Total Project Cost | $20,725,000 |

Financial Performance & ROI

The system consistently produces 150 tons of marketable product per day.

Scenario 1 — Premium Animal Feed Pellets

Metric | Value |

Market Sale Price | $300/ton |

Annual Revenue (350 days) | $15,750,000 |

Annual Operating Cost | $1,071,098.70 |

Net Annual Profit | ~$14,678,901.30 |

Estimated Payback | ≈ 1.4 Years (adjusted for updated capex) |

Scenario 2 — Organic Fertilizer Pellets

Metric | Value |

Market Sale Price | $250/ton |

Annual Revenue (350 days) | $13,125,000 |

Annual Operating Cost | $1,071,098.70 |

Net Annual Profit | ~$12,053,901.30 |

Estimated Payback | ≈ 1.7 Years (adjusted for updated capex) |

Animal Feed remains the highest-margin pathway and is the recommended launch strategy.

Phased Production Strategy

Phase One — Revenue Optimization

Begin production with Premium Animal Feed Pellets to accelerate capital recovery.

Phase Two — Brand Sustainability Signature

Introduce Organic Fertilizer Pellets for:

- The Resort’s landscaping and gardens

- Partner farms and local eco-agriculture networks

- Branded sustainability storytelling

This creates both financial leadership and authentic environmental stewardship.

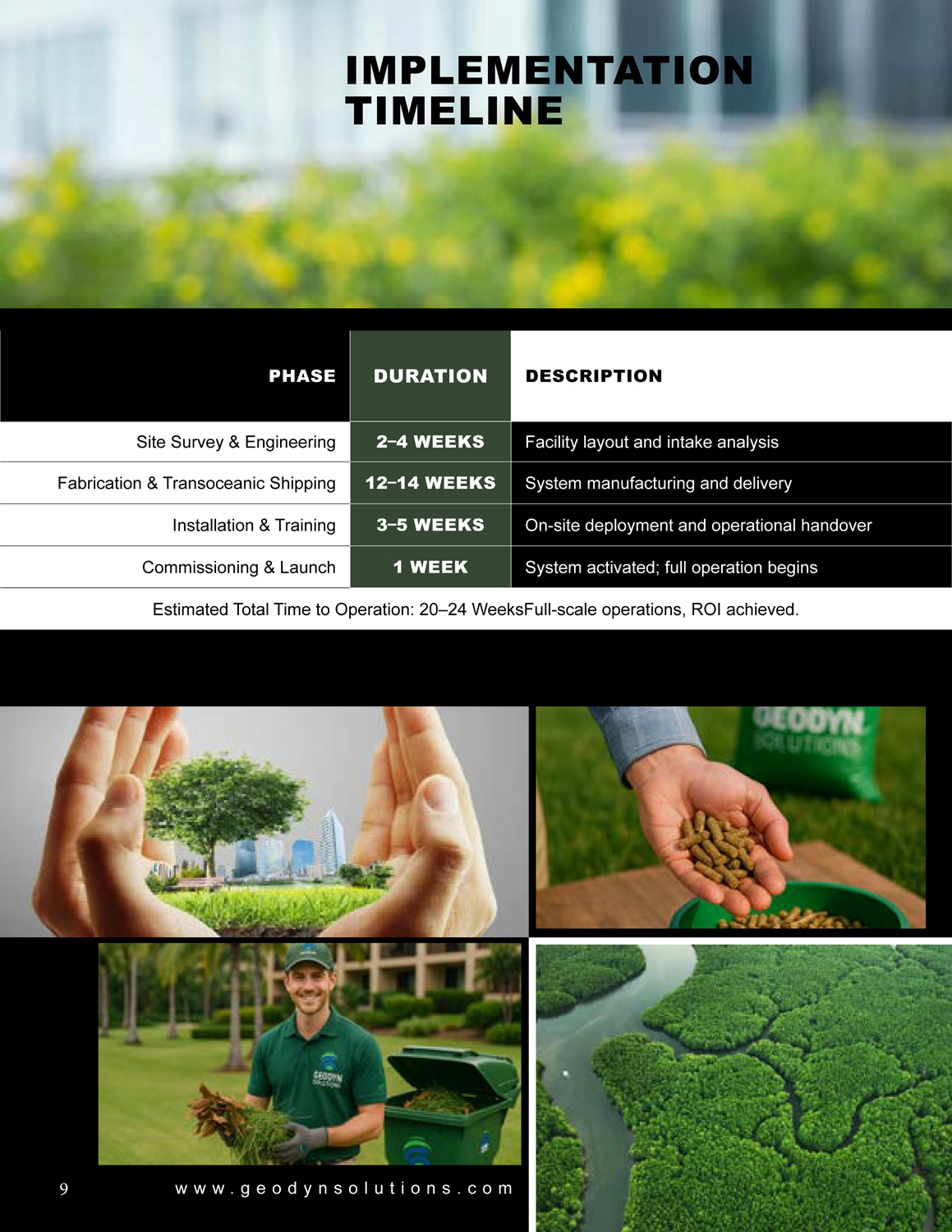

Implementation Timeline

Phase | Duration | Description |

Site Survey & Engineering | 2–4 Weeks | Facility layout and intake analysis |

Fabrication & Transoceanic Shipping | 12–14 Weeks | System manufacturing and delivery |

Installation & Training | 3–5 Weeks | On-site deployment and operational handover |

Commissioning & Launch | 1 Week | System activated; full operation begins |

Estimated Total Time to Operation: 20–24 Weeks

Conclusion

By adopting the Geodyn 15 TPH Waste Conversion System, The Resort will:

- Lead the Caribbean luxury segment in climate-positive operations

- Reduce operational waste handling costs and landfill dependency

- Generate substantial recurring revenue streams

- Offer guests a visible, meaningful sustainability experience

- Move toward a fully circular resource economy model

Geodyn Solutions stands ready to provide full engineering, installation, operational training, and ongoing support.