Comprehensive Business Proposal: Powering a 1,000 MWh Plant with Solid Carbon Fractionation

Executive Summary

Geodyn Solutions proposes an innovative approach to energy generation by utilizing Solid Carbon Fractionation (SCF) technology to create a clean, high-value fuel for a 1,000 MWh power plant. This proposal outlines the technical approach, capital and operational cost estimates, job creation potential, economic benefits for the coal industry, carbon credit advantages, and return on investment (ROI) to showcase the feasibility and profitability of the project.

Project Overview

Objective

To develop a 1,000 MWh power plant powered by a turbine and Rankine Organic Cycle (ROC) system using fuel derived from SCF technology, which fractionates solid hydrocarbons into clean-burning fuel while reducing emissions.

Key Highlights

- Fuel Source: High-purity solid carbon fraction derived from coal via SCF technology.

- Coal Utilization: Efficiently processes coal to maximize energy yield and reduce waste.

- Power Generation System: Combined turbine and ROC for maximum efficiency.

- Environmental Benefits: Drastic reduction in sulfur, mercury, and CO₂ emissions.

- Economic Growth: Increased demand for coal supply, boosting coal industry jobs and infrastructure.

- Job Creation: Significant employment opportunities in construction, operations, maintenance, and coal supply logistics.

- Carbon Credit Advantages: Eligibility for carbon credits due to cleaner energy production.

Technical Approach

Solid Carbon Fractionation Process

SCF involves thermal cracking and controlled distillation of coal to separate valuable energy components. This produces:

- Liquid hydrocarbons (diesel, kerosene, jet fuel equivalents).

- Hydrogen-rich gases for combustion or secondary energy use.

- Ultra-purified solid carbon (low-sulfur fuel for power generation).

Coal Requirements for Power Generation

To sustain a 1,000 MWh power plant utilizing SCF fuel, the estimated coal requirement is:

- Coal Consumption: ~6,000 tons of coal per day.

- Annual Coal Demand: ~2.2 million tons per year.

- Coal-to-Fuel Efficiency: SCF technology ensures maximum conversion efficiency, reducing waste and optimizing energy output.

- Supply Chain Impact: Increased coal production and transportation demand will directly benefit mining operations and associated industries.

Power Plant Design

The 1,000 MWh plant will integrate:

- High-efficiency combustion turbinesutilizing SCF-generated fuels.

- Rankine Organic Cycle (ROC) systemto maximize thermal energy recovery.

- Flue gas recapture technologyto minimize environmental impact.

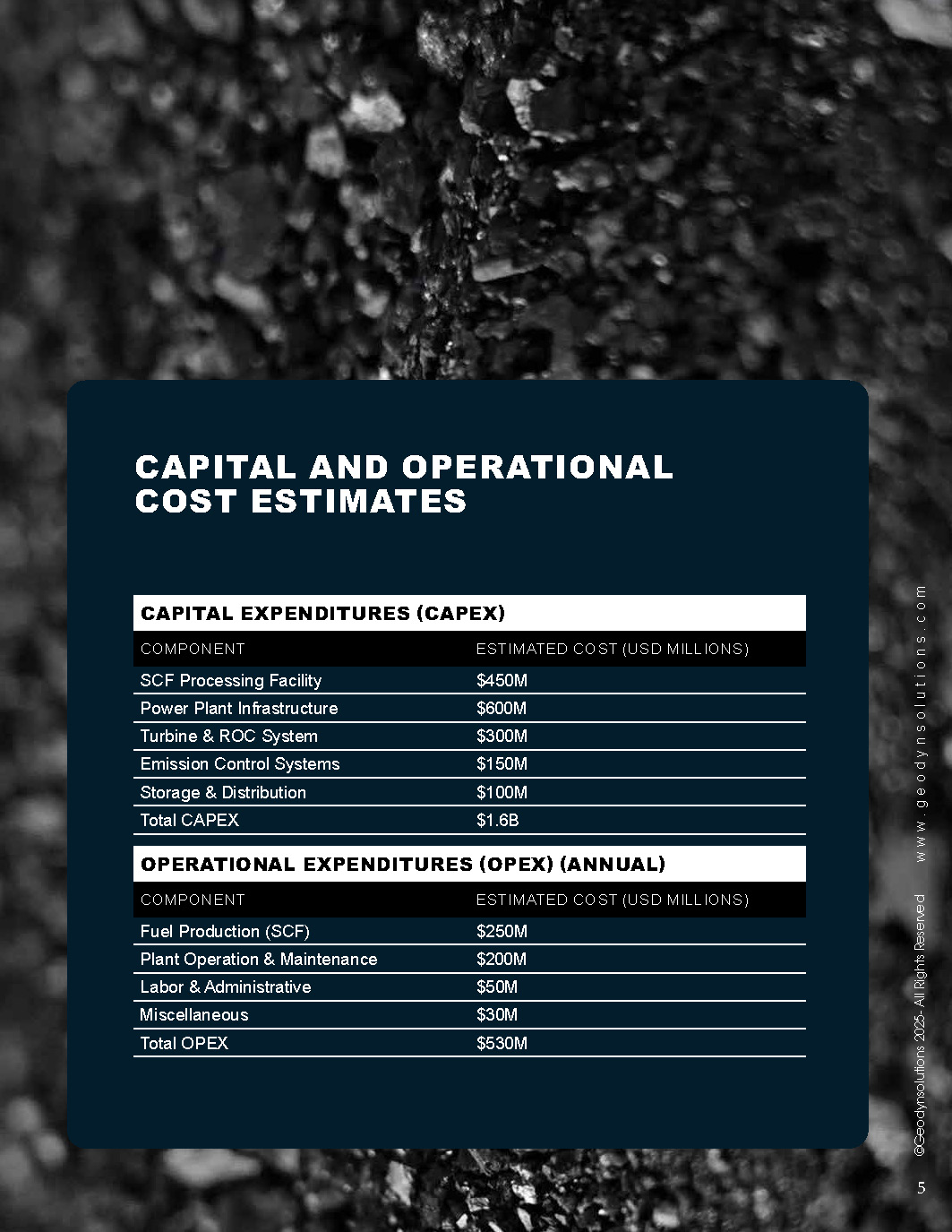

Capital and Operational Cost Estimates

Capital Expenditures (CAPEX)

Component | Estimated Cost (USD Millions) |

SCF Processing Facility | $450M |

Power Plant Infrastructure | $600M |

Turbine & ROC System | $300M |

Emission Control Systems | $150M |

Storage & Distribution | $100M |

Total CAPEX | $1.6B |

Operational Expenditures (OPEX) (Annual)

Component | Estimated Cost (USD Millions) |

Fuel Production (SCF) | $250M |

Plant Operation & Maintenance | $200M |

Labor & Administrative | $50M |

Miscellaneous | $30M |

Total OPEX | $530M |

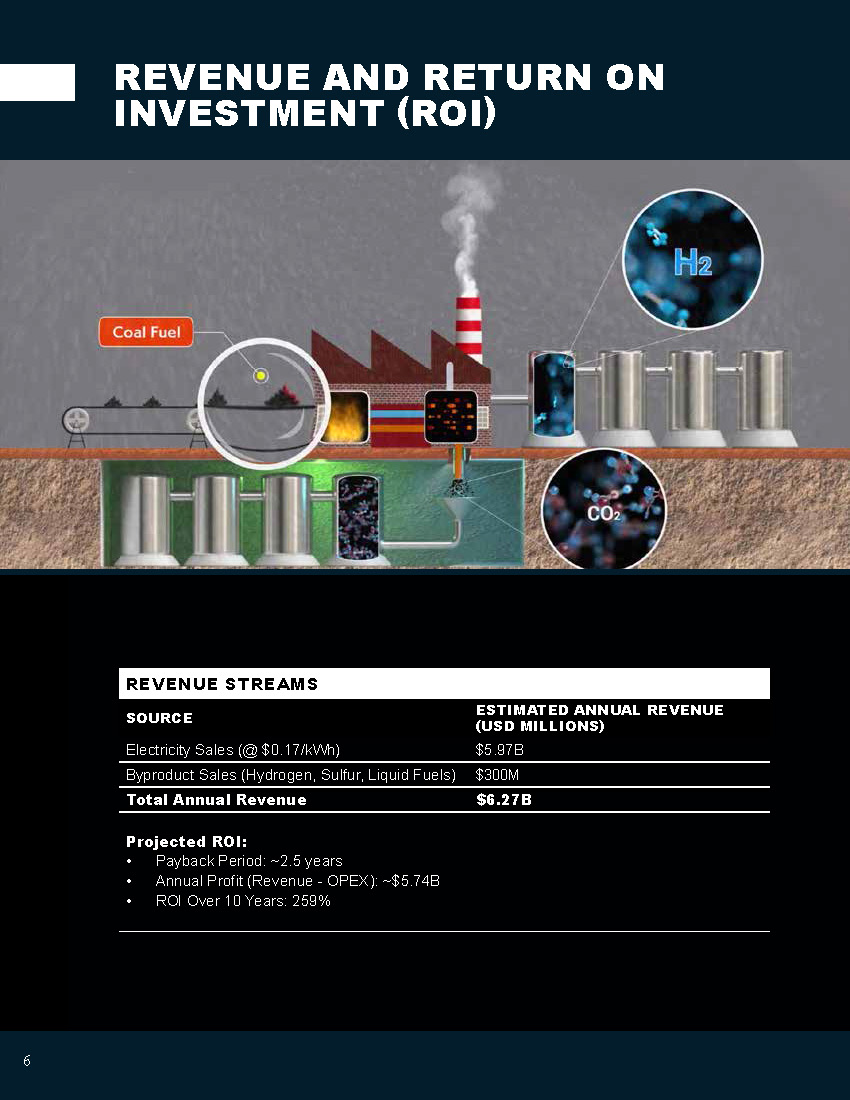

Revenue and Return on Investment (ROI)

Revenue Streams

Source | Estimated Annual Revenue (USD Millions) |

Electricity Sales (@ $0.17/kWh) | $5.97B |

Byproduct Sales (Hydrogen, Sulfur, Liquid Fuels) | $300M |

Total Annual Revenue | $6.27B |

Projected ROI

- Payback Period: ~2.5 years

- Annual Profit (Revenue – OPEX): ~$5.74B

- ROI Over 10 Years: 259%

Job Creation & Economic Impact

The project will generate significant employment opportunities, including:

- Construction Phase:~3,500 jobs for facility and infrastructure development.

- Operations & Maintenance:~1,000 long-term jobs for plant operation, fuel processing, and logistics.

- Coal Supply & Mining Industry:Demand for ~2.2 million tons of coal annually supports thousands of mining, transportation, and processing jobs.

- Supply Chain & Support Industries:Additional ~2,000 jobs in transportation, equipment manufacturing, and related services.

- Local Economic Boost:Increased demand for housing, food services, and retail in surrounding communities.

Coal Industry Benefits & National Economic Impact

- Revitalization of the Coal Industry: Increased coal demand secures mining operations and stabilizes jobs in coal-producing regions.

- Infrastructure Development: Strengthens coal transportation networks, railways, and port facilities.

- Energy Independence: Reduces reliance on imported fuels by leveraging domestic coal reserves.

- Long-Term Industry Stability: Establishes a sustainable market for coalbeyond traditional combustion methods, ensuring long-term viability.

- Boosts National GDP: Increased mining, transport, and energy production contribute to overall economic growth.

Carbon Credit & Environmental Advantages

- Lower Emissions Profile: SCF significantly reduces sulfur, mercury, and CO₂ emissionscompared to traditional coal combustion.

- Carbon Credit Eligibility: The cleaner energy output makes the project eligible for carbon credit trading, offering financial incentives for emission reductions.

- Circular Economy Benefits: Captures and repurposes byproducts such as hydrogen and sulfur into valuable commodities, minimizing waste.

- Regulatory Compliance: Meets EPA and international environmental standards, reducing penalties and increasing market viability for cleaner coal energy.

Conclusion & Next Steps

This proposal demonstrates a financially viable and environmentally sustainable energy model utilizing Solid Carbon Fractionation. Geodyn Solutions seeks investment partnerships, regulatory approvals, and infrastructure development collaboration to bring this vision to reality.

Proposed Timeline

- Phase 1 (12 Months):Feasibility Study & Permitting

- Phase 2 (24 Months):Infrastructure Development & SCF Facility Construction

- Phase 3 (12 Months):Power Plant Commissioning & Initial Operations

We welcome discussions with investors, policymakers, and industry stakeholders to accelerate the deployment of this next-generation coal technology.