Geodyn 15 TPH Circular Sustainability & Revenue Initiative

Executive Summary

The Resort has the opportunity to implement a world-class sustainability and revenue initiative centered on circular resource management. By installing the Geodyn 15 Ton-Per-Hour Total Waste Conversion System, the Resort will convert its daily organic waste streams — food scraps, plant material, and biodegradable refuse — into high-value agricultural commodities, specifically premium livestock feed pellets or organic fertilizer pellets.

This shift eliminates reliance on landfill disposal, reduces environmental impact, elevates ESG and green-tourism credentials, and creates a predictable, recurring revenue stream.

The Geodyn System operates with no combustion, no smoke, and no odor. Through indirect radiant heat processing, material becomes fully sterilized and market-ready in under 30 minutes, producing a stable, value-rich output suitable for sale or internal reuse. The system is permitted in California — one of the most environmentally regulated jurisdictions in the world.

This initiative allows The Resort to move confidently toward a fully circular and regenerative operational model, reflecting the values of the modern luxury traveler: wellness, nature stewardship, and environmental accountability.

Strategic Value to The Resort

Impact Category | Benefit |

Environmental Leadership | Eliminates landfill dependency; significantly reduces waste footprint |

Brand Positioning | Establishes The Resort as a regional leader in sustainability-driven luxury |

Financial Performance | Creates strong recurring revenue through saleable agricultural commodities |

Guest Experience | Aligns with wellness tourism, sustainability culture, and experiential authenticity |

Regulatory Alignment | Meets and exceeds environmental standards while reducing long-term liability |

This project positions The Resort as a benchmark sustainability destination in the Caribbean.

System Overview

System Capability | Specification |

Input Capacity | 300 tons/day organic waste |

Output Capacity | 150 tons/day of finished pellets (feed or fertilizer) |

Processing Time | < 30 minutes, continuous flow |

Pathogen Elimination | 100% sterilization via indirect radiant heat |

Emissions | Zero incineration, zero odor, zero airborne emissions |

Water Circularity | Water extracted during processing is purified for irrigation and operational reuse |

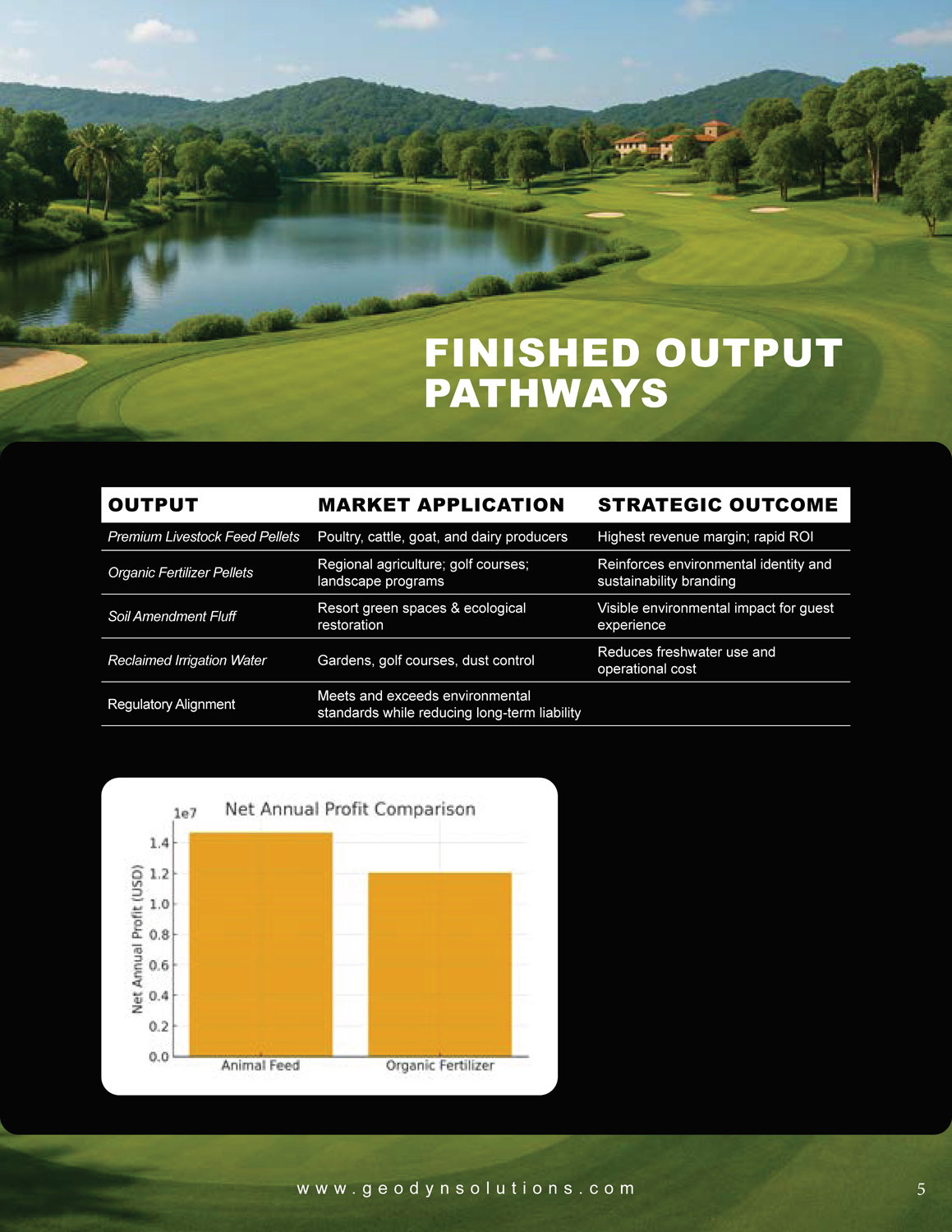

Finished Output Pathways

Output | Market Application | Strategic Outcome |

Premium Livestock Feed Pellets | Poultry, cattle, goat, and dairy producers | Highest revenue margin; rapid ROI |

Organic Fertilizer Pellets | Regional agriculture; golf courses; landscape programs | Reinforces environmental identity and sustainability branding |

Soil Amendment Fluff | Resort green spaces & ecological restoration | Visible environmental impact for guest experience |

Reclaimed Irrigation Water | Gardens, golf courses, dust control | Reduces freshwater use and operational cost |

Capital Requirement (Updated)

Item | Cost (USD) |

Geodyn 15 TPH System | $19,470,000 |

Shipping, Installation, Training & Commissioning | $1,255,000 |

Total Project Cost | $20,725,000 |

Financial Performance & ROI

The system consistently produces 150 tons of marketable product per day.

Scenario 1 — Premium Animal Feed Pellets

Metric | Value |

Market Sale Price | $300/ton |

Annual Revenue (350 days) | $15,750,000 |

Annual Operating Cost | $1,071,098.70 |

Net Annual Profit | ~$14,678,901.30 |

Estimated Payback | ≈ 1.4 Years (adjusted for updated capex) |

Scenario 2 — Organic Fertilizer Pellets

Metric | Value |

Market Sale Price | $250/ton |

Annual Revenue (350 days) | $13,125,000 |

Annual Operating Cost | $1,071,098.70 |

Net Annual Profit | ~$12,053,901.30 |

Estimated Payback | ≈ 1.7 Years (adjusted for updated capex) |

Animal Feed remains the highest-margin pathway and is the recommended launch strategy.

Phased Production Strategy

Phase One — Revenue Optimization

Begin production with Premium Animal Feed Pellets to accelerate capital recovery.

Phase Two — Brand Sustainability Signature

Introduce Organic Fertilizer Pellets for:

- The Resort’s landscaping and gardens

- Partner farms and local eco-agriculture networks

- Branded sustainability storytelling

This creates both financial leadership and authentic environmental stewardship.

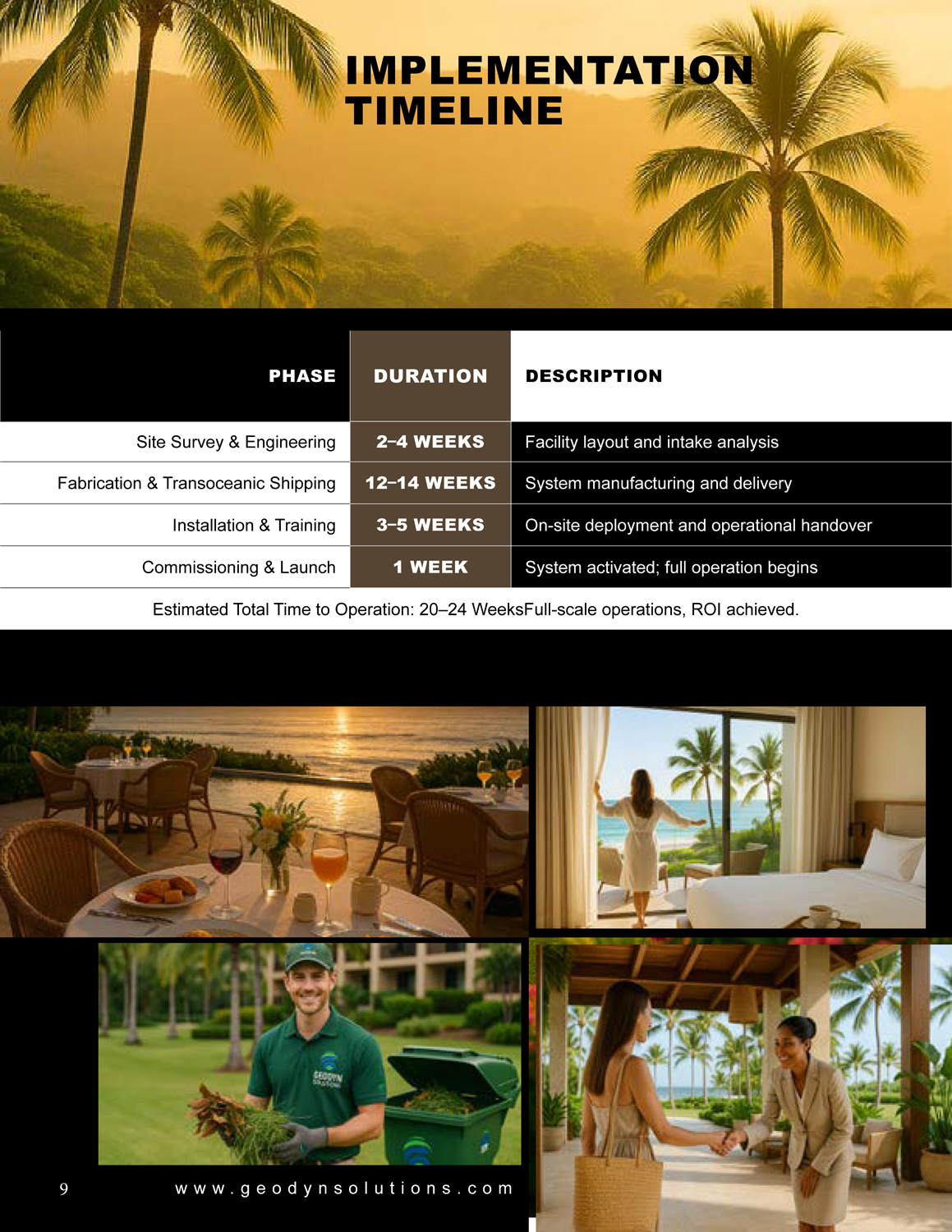

Implementation Timeline

Phase | Duration | Description |

Site Survey & Engineering | 2–4 Weeks | Facility layout and intake analysis |

Fabrication & Transoceanic Shipping | 12–14 Weeks | System manufacturing and delivery |

Installation & Training | 3–5 Weeks | On-site deployment and operational handover |

Commissioning & Launch | 1 Week | System activated; full operation begins |

Estimated Total Time to Operation: 20–24 Weeks

Conclusion

By adopting the Geodyn 15 TPH Waste Conversion System, The Resort will:

- Lead the Caribbean luxury segment in climate-positive operations

- Reduce operational waste handling costs and landfill dependency

- Generate substantial recurring revenue streams

- Offer guests a visible, meaningful sustainability experience

- Move toward a fully circular resource economy model

Geodyn Solutions stands ready to provide full engineering, installation, operational training, and ongoing support.