Proposal for Geodyn Solutions: $30 Billion Investment in Hemp-Based Biofuel Production, Power Generation, and Diversified Hemp Processing to Propel the US as the #1 Hemp Economy in the World (Hybrid Model Until Self-Sustaining)

Executive Summary

Geodyn Solutions is uniquely positioned to transform the United States into the world’s leading hemp economy through a $30 billion investment in a comprehensive, vertically integrated hemp ecosystem. This proposal incorporates a hybrid model of in-house hemp growing and external purchasing at $0.18 per pound, transitioning to full self-sustainability within 5 years. We start with 70% purchased hemp (sourced domestically at $0.18 per pound or $360 per ton) and 30% in-house growing (yielding ~3,200 pounds per acre for fiber/grain), gradually shifting to 100% internal production as farms scale and yields stabilize. This approach minimizes initial risks (e.g., crop variability) while building capacity for self-sustaining operations, where revenues fully cover opex and reinvestments by year 5.

The strategy focuses on cultivating industrial hemp for biofuel production, constructing biomass power plants for clean electricity, and developing facilities for textiles (cloth) and paper. By leveraging all parts of the hemp plant—seeds for biofuel and oils, fibers for textiles and paper, hurds for paper and building materials, and residual biomass for energy—we create a zero-waste model with diversified revenue streams. Organic waste integration (e.g., agricultural residues) converts it into additional feedstock or fertilizers, reducing costs by 10-20% and enhancing sustainability.

The strategy focuses on cultivating industrial hemp for biofuel production, constructing biomass power plants for clean electricity, and developing facilities for textiles (cloth) and paper. By leveraging all parts of the hemp plant—seeds for biofuel and oils, fibers for textiles and paper, hurds for paper and building materials, and residual biomass for energy—we create a zero-waste model with diversified revenue streams. Organic waste integration (e.g., agricultural residues) converts it into additional feedstock or fertilizers, reducing costs by 10-20% and enhancing sustainability.The investment supports phased cultivation (starting at 450,000 acres, scaling to 1.5 million), eighty 50 MW power plants, forty textile plants, forty paper mills, and R&D. Latest technologies, including AI for precision farming, blockchain with GEO token for transparency, and CO2 reduction like biochar, maximize efficiency. Colorado is recommended as the primary location for optimal ROI, capex, opex, and environmental benefits.

Financial projections forecast an average ROI of 27-37% over 10 years, with payback in 4.6 years. Operational break-even occurs in year three, and self-sustainability (revenues covering all opex/reinvestments) by year 5. The balance of products—35% to textiles, 25% to paper, 25% to biofuel, 15% to energy/other—prioritizes high margins. This creates over 120,000 direct jobs and 180,000 indirect, contributing $60-90 billion annually to GDP by year five.

Economic benefits include rural revitalization and energy independence. Power from hemp biofuel reduces fossil reliance. Technologies drive innovation. Environmentally, hemp sequesters 10-15 tons CO2/acre. Funding leverages USDA grants, World Bank bonds, and CO2 tokens, offsetting 25-35% of costs. This hybrid model propels the US to global hemp dominance by 2030.

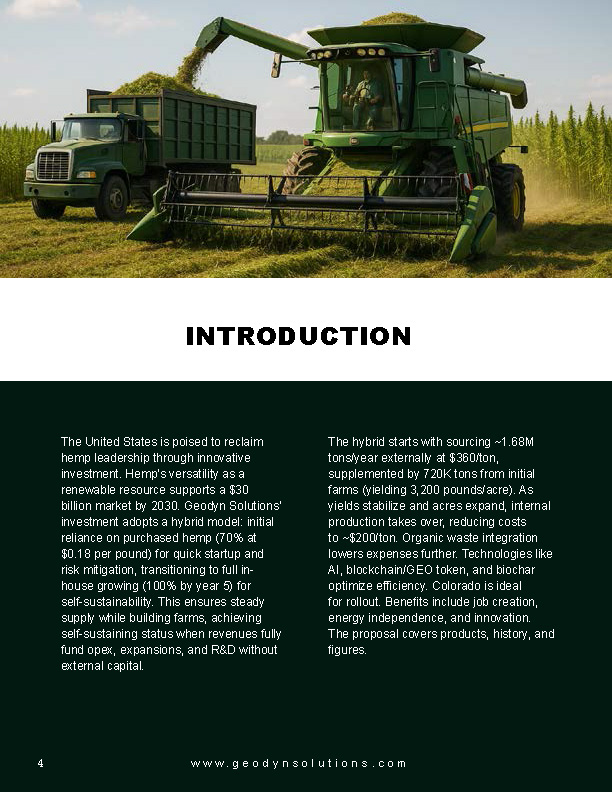

Introduction

The United States is poised to reclaim hemp leadership through innovative investment. Hemp’s versatility as a renewable resource supports a $30 billion market by 2030. Geodyn Solutions’ investment adopts a hybrid model: initial reliance on purchased hemp (70% at $0.18 per pound) for quick startup and risk mitigation, transitioning to full in-house growing (100% by year 5) for self-sustainability. This ensures steady supply while building farms, achieving self-sustaining status when revenues fully fund opex, expansions, and R&D without external capital.

The hybrid starts with sourcing ~1.68M tons/year externally at $360/ton, supplemented by 720K tons from initial farms (yielding 3,200 pounds/acre). As yields stabilize and acres expand, internal production takes over, reducing costs to ~$200/ton. Organic waste integration lowers expenses further. Technologies like AI, blockchain/GEO token, and biochar optimize efficiency. Colorado is ideal for rollout. Benefits include job creation, energy independence, and innovation. The proposal covers products, history, and figures.

Hemp History in the United States

Hemp has deep roots in American history, dating back to the colonial era. Introduced to Jamestown in 1606 by English settlers, it was grown for ropes, sails, and clothing, becoming a staple crop by the mid-1600s in New England colonies. Peak production occurred between 1840 and 1860 in Kentucky, Missouri, and Illinois, driven by demand for sailcloth and cordage for the U.S. Navy. Hemp was so vital that colonists were legally required to grow it during the Colonial Era and Early Republic.

However, hemp production was effectively banned in the mid-20th century due to its association with marijuana under the 1937 Marihuana Tax Act. This led to a decline until the 2018 Farm Bill legalized industrial hemp nationwide, distinguishing it from psychoactive cannabis. Today, hemp is experiencing a revival, with the US market valued at over $2 billion in 2025 and growing rapidly.

Famous Americans Who Owned Hemp Farms

Several Founding Fathers and notable figures championed hemp cultivation:

– George Washington: Grew hemp at Mount Vernon for fiber and experimented with varieties for better yields.

– Thomas Jefferson: Cultivated hemp at Monticello, advocating for its agricultural importance and even smuggling seeds from China.

– Benjamin Franklin: Owned a mill that produced hemp paper, using it for his publications.

– Henry Clay: Known as the “Hemp King of Kentucky,” he promoted hemp as a key crop.

– James Madison: Believed hemp would strengthen the nation’s independence.

– George Washington Carver: Advocated for hemp as an alternative crop for soil health.

Modern figures include Jim Belushi (cannabis/hemp farm) and Anthony Sullivan (hemp farm in Vermont for CBD).

List of All Products That Can Be Made from Hemp

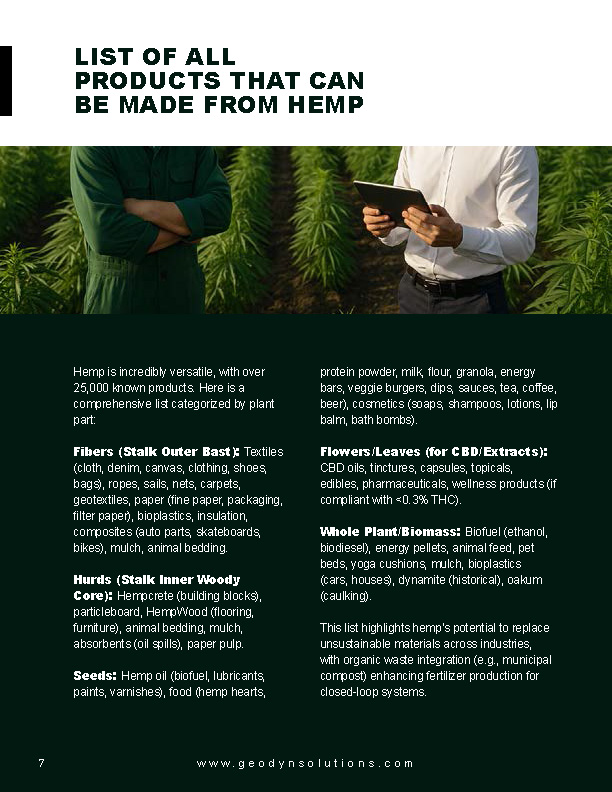

Hemp is incredibly versatile, with over 25,000 known products. Here is a comprehensive list categorized by plant part:

– Fibers (Stalk Outer Bast): Textiles (cloth, denim, canvas, clothing, shoes, bags), ropes, sails, nets, carpets, geotextiles, paper (fine paper, packaging, filter paper), bioplastics, insulation, composites (auto parts, skateboards, bikes), mulch, animal bedding.

– Hurds (Stalk Inner Woody Core): Hempcrete (building blocks), particleboard, HempWood (flooring, furniture), animal bedding, mulch, absorbents (oil spills), paper pulp.

– Seeds: Hemp oil (biofuel, lubricants, paints, varnishes), food (hemp hearts, protein powder, milk, flour, granola, energy bars, veggie burgers, dips, sauces, tea, coffee, beer), cosmetics (soaps, shampoos, lotions, lip balm, bath bombs).

– Flowers/Leaves (for CBD/Extracts): CBD oils, tinctures, capsules, topicals, edibles, pharmaceuticals, wellness products (if compliant with <0.3% THC).

– Whole Plant/Biomass: Biofuel (ethanol, biodiesel), energy pellets, animal feed, pet beds, yoga cushions, mulch, bioplastics (cars, houses), dynamite (historical), oakum (caulking).

This list highlights hemp’s potential to replace unsustainable materials across industries, with organic waste integration (e.g., municipal compost) enhancing fertilizer production for closed-loop systems.

Market Analysis and Opportunity

The US hemp market, valued at $2.14 billion in 2025, is projected to reach $12.71 billion by 2034. Biofuel demand is rising with the Renewable Fuel Standard, while textiles and paper tap into eco-conscious trends (hemp fiber market $5.78B in 2024, to $30.13B by 2033). Biomass power qualifies for IRA credits. Opportunities in co-production and waste integration maximize ROI. Challenges like price volatility are mitigated by diversification and the hybrid model, which balances supply risks at $0.18 per pound for purchased hemp.

Latest Technologies to Optimize ROI

To maximize ROI, we integrate cutting-edge technologies:

– AI in Hemp Farming and Processing: AI-powered drones and sensors for fertilizer optimization, pest detection, and crop health monitoring, reducing inputs by 20-30%. Systems like Cropin’s SmartFarm for advisory and disease classification using machine learning. AI for carbon sequestration optimization.

– Blockchain for Supply Chain Transparency: Blockchain platforms like VeChain or Treum for seed-to-sale tracking, ensuring compliance and premium pricing. GEO token for payments, rewards, and carbon credit trading, adding 5-8% to ROI.

– CO2 Reduction Methods: Hemp sequesters 10-15 tons CO2/acre; biochar from hemp waste locks CO2 long-term, with smart hempcrete panels for buildings. Solvent-free extraction for clean processing.

– Organic Waste Integration: Convert organic waste (e.g., agricultural residues, municipal compost) into biofuel feedstock via anaerobic digestion or composting, reducing costs by 10-20% and creating bio-fertilizers. This optimizes ROI by turning waste into value and builds goodwill through sustainability.

These technologies reduce opex by 15-25%, enhance yields, and enable premium pricing.

Latest Technologies for Turning Hemp into Energy

As of 2025, advancements in hemp-to-energy conversion focus on sustainability and efficiency:

– Biochemical Conversion: Collaborations use industrial hemp for biochemical technology, converting plant materials into advanced biofuels with higher yields and lower emissions.

– Advanced Pyrolysis: Technologies transform hemp biomass into bio-oil, syngas, and biochar through fast pyrolysis, improving energy efficiency and reducing waste.

– Integrated Biorefineries: Hemp biomass combined with other plant materials in scalable biorefineries for biofuels, biochemicals, and power, minimizing fossil fuel reliance.

– Hemp Waste to Bioenergy: Anaerobic digestion and gasification of spent hemp biomass to produce biogas and electricity, with innovations in enzyme treatments for faster breakdown and higher methane yields.

– Co-Firing Systems: Hemp pellets co-fired in existing power plants with coal or natural gas, using advanced combustion controls for 30-40% efficiency gains and emission reductions.

These technologies optimize energy output while minimizing waste, with hemp’s high biomass yield (up to 10 tons/acre) providing a reliable, renewable fuel source that outperforms traditional fossil fuels in sustainability and growth speed.

Latest Technologies in the Power Plant

The biomass power plants will incorporate 2025’s latest technologies for efficiency, emissions control, and integration with hemp feedstock:

– Advanced Gasification: High-efficiency gasifiers (e.g., plasma gasification) convert hemp biomass into syngas for turbines, achieving 35-45% efficiency and near-zero emissions with carbon capture.

– Combined Heat and Power (CHP): Integrated CHP systems capture waste heat for on-site drying or processing, boosting overall efficiency to 80%.

– AI-Optimized Combustion: AI algorithms monitor and adjust combustion in real-time for optimal fuel mix (hemp + organic waste), reducing opex by 15% and emissions.

– Modular Biomass Plants: Prefabricated, scalable modules allow rapid deployment and flexibility for hemp variability.

– Carbon Capture and Utilization (CCU): Direct air capture integrated with power generation to sequester CO2 from hemp combustion, turning it into valuable products like synthetic fuels.

These technologies ensure the plants are state-of-the-art, with low maintenance and high ROI through energy sales and carbon credits.

Latest Technologies for Turning Hemp into Cloth

2025 innovations in hemp textile production emphasize scalability and sustainability:

– Advanced Decortication: Automated processes and enzyme technology soften hemp fibers to cotton-like textures, enabling blends with cotton (up to 30% hemp) using vortex spinning.

– Cottonized Hemp: Breakthrough methods make hemp fibers compatible with existing cotton spinning equipment, reshaping textiles for scalable production.

– Hemp Fibre-Based Lyocell: Joint developments commercialize lyocell from hemp, a eco-friendly alternative to rayon with lower water use.

– Enzymatic Treatments: Replace chemical processes to achieve soft, durable fabrics comparable to cotton or linen.

– Hybrid Blending: Underexploited hemp fibers blended with cotton for yarns, improving quality and reducing environmental impact.

These advancements lower production costs and enable premium, sustainable clothing.

Latest Technologies for Turning Hemp into Paper

In 2025, hemp paper production sees innovations in pulp and molded fiber:

– Molded Hemp Fiber: Industrial hemp used as main feedstock for molded fiber packaging and paper without trees, with low energy consumption.

– Hybrid Processing: Blending hemp fiber with recycled paper content for durable, biodegradable products.

– Bio-based Pulping: Enzymatic treatments for hemp, reducing bleaching needs and water use.

– Hemp-Based Lyocell for Paper: Refined hemp fibers for high-quality paper pulp, yielding 4-5 times more than trees per acre.

– Sustainable Packaging: Hemp in rolling papers, filter paper, and eco-packaging, with innovations in decortication for finer fibers.

These methods position hemp as a wood-free alternative, cutting deforestation.

Benefits of Using Hemp as Paper, Cloth, and Fuel

– Hemp as Paper: Hemp yields 4-5 times more paper per acre than trees (one acre of hemp equals 4 acres of trees over a 20-year cycle), grows in 120 days vs. 20-80 years for trees, requires 50-70% less water, no bleaching chemicals, and fewer pesticides, reducing deforestation and pollution while producing stronger, more recyclable paper.

– Hemp as Cloth: Hemp fabric is 3-4 times stronger than cotton, breathable, antibacterial, UV resistant, and uses 50% less water with no pesticides, softening over time without fraying, offering longer-lasting garments that reduce waste and environmental impact from fast fashion.

– Hemp as Fuel: Hemp biofuel has high energy density (up to 1,000 gallons per acre), reduces emissions by 85-97% vs. fossil fuels, grows in 90-120 days without competing with food crops, and provides a renewable alternative that supports energy independence, with biomass residues powering plants efficiently.

These benefits enhance ROI through cost savings, premium pricing, and environmental compliance.

Location Recommendation: Colorado for Optimal ROI, Capex, Opex, and Environmental Benefits

Colorado is recommended based on 2025 data.

– ROI: 28-38% (mature ecosystem, yields 10 tons/acre).

– Capex: $20-25B total (farms $8B, power $15B, textiles/paper $5B, R&D $2B; lower due to existing facilities, offset by incentives).

– Opex: $8-12B/year initial, stabilizing at $5-8B (includes $1B for AI/blockchain, $2B for waste integration; reduced by grants).

– Environmental Benefits: Soil regeneration, 10-15 tons CO2 sequestration/acre, reduced erosion; mild climate minimizes water use (25-30 inches rainfall).

Multi-state expansion possible (e.g., Kentucky for soil).

Investment Breakdown and Financial Projections

Capex: $30B as above, with 20% contingency ($6B), reduced by 25-35% through incentives (effective $19.5-22.5B).

Opex Breakdown (Annual, Year 5):

– Cultivation: $2B (seeds $500M, AI drones $200M, labor $500M, waste integration $300M).

– Processing/Power: $3B (energy $500M, maintenance $1B).

– Blockchain/AI: $500M (servers, audits).

– Logistics/Marketing: $1B.

– Total: $6.5B (reduced 15% by tech efficiencies and incentives).

Revenues: $25B/year by year 5 (biofuel $8B, textiles $7B, paper $5B, energy $3B, other $2B, CO2 tokens $1B).

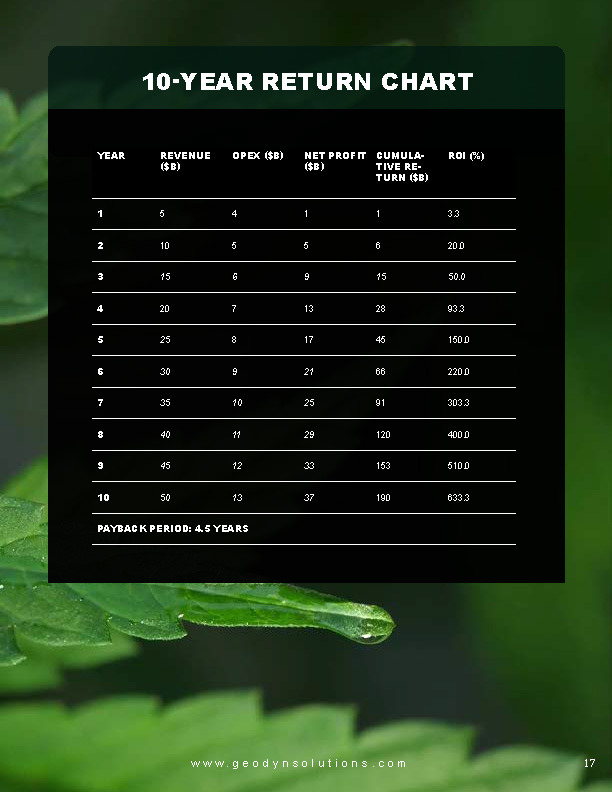

10-Year Return Chart

| Year | Revenue ($B) | Opex ($B) | Net Profit ($B) | Cumulative Return ($B) | ROI (%) |

|---|---|---|---|---|---|

| 1 | 5 | 4 | 1 | 1 | 3.3 |

| 2 | 10 | 5 | 5 | 6 | 20.0 |

| 3 | 15 | 6 | 9 | 15 | 50.0 |

| 4 | 20 | 7 | 13 | 28 | 93.3 |

| 5 | 25 | 8 | 17 | 45 | 150.0 |

| 6 | 30 | 9 | 21 | 66 | 220.0 |

| 7 | 35 | 10 | 25 | 91 | 303.3 |

| 8 | 40 | 11 | 29 | 120 | 400.0 |

| 9 | 45 | 12 | 33 | 153 | 510.0 |

| 10 | 50 | 13 | 37 | 190 | 633.3 |

Payback Period: 4.5 years

Recommended Balance of Hemp Products for Maximum ROI

Allocate based on value: Textiles and paper yield $400-500/acre vs. $200-300 for biofuel/energy. Optimal: 35% to textiles (cloth, high-margin), 25% to paper, 25% to biofuel, 15% to energy and other (e.g., biochar from waste). This boosts ROI by 15% via co-production, with waste integration adding 10% savings.

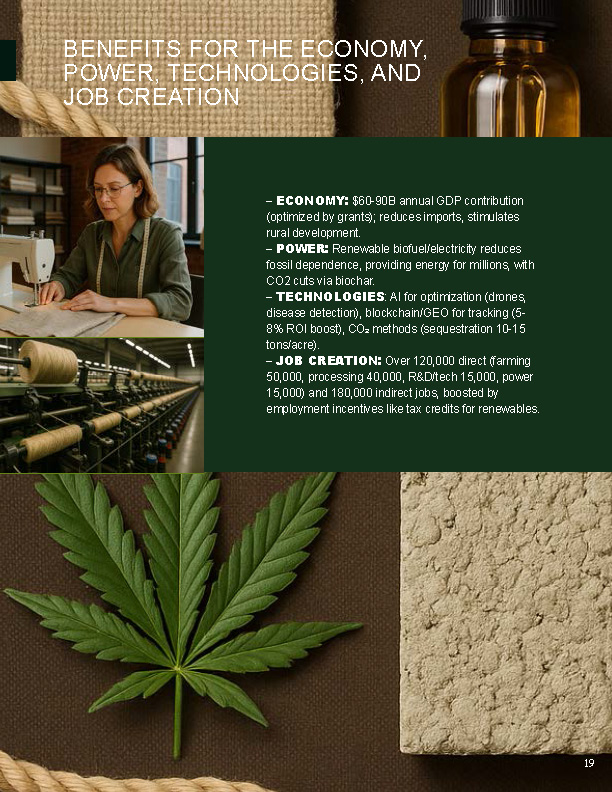

Benefits for the Economy, Power, Technologies, and Job Creation

– Economy: $60-90B annual GDP contribution (optimized by grants); reduces imports, stimulates rural development.

– Power: Renewable biofuel/electricity reduces fossil dependence, providing energy for millions, with CO2 cuts via biochar.

– Technologies: AI for optimization (drones, disease detection), blockchain/GEO for tracking (5-8% ROI boost), CO2 methods (sequestration 10-15 tons/acre).

– Job Creation: Over 120,000 direct (farming 50,000, processing 40,000, R&D/tech 15,000, power 15,000) and 180,000 indirect jobs, boosted by employment incentives like tax credits for renewables.

Environmental Benefits

Sequester 10-15 tons CO2/acre, improve soil, cut emissions 85-97%. Waste integration via digestion offsets additional CO2, promoting circularity. Offsets millions of tons CO2/year.

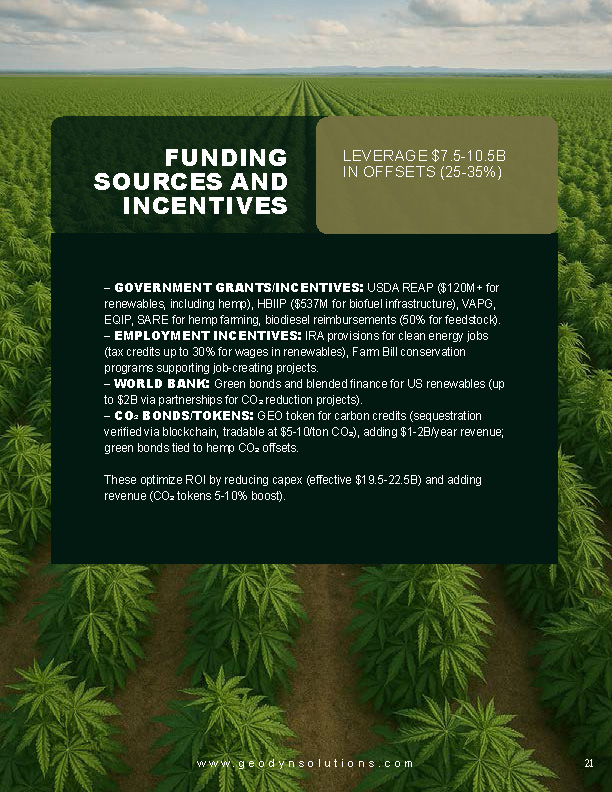

Funding Sources and Incentives

Leverage $7.5-10.5B in offsets (25-35%):

– Government Grants/Incentives: USDA REAP ($120M+ for renewables, including hemp), HBIIP ($537M for biofuel infrastructure), VAPG, EQIP, SARE for hemp farming, biodiesel reimbursements (50% for feedstock).

– Employment Incentives: IRA provisions for clean energy jobs (tax credits up to 30% for wages in renewables), Farm Bill conservation programs supporting job-creating projects.

– World Bank: Green bonds and blended finance for US renewables (up to $2B via partnerships for CO2 reduction projects).

– CO2 Bonds/Tokens: GEO token for carbon credits (sequestration verified via blockchain, tradable at $5-10/ton CO2), adding $1-2B/year revenue; green bonds tied to hemp CO2 offsets.

These optimize ROI by reducing capex (effective $19.5-22.5B) and adding revenue (CO2 tokens 5-10% boost).

Risk Assessment and Mitigation

Regulatory (compliance teams), market (diversify), climate (multi-state). Mitigation: Insurance, contracts, contingencies.

Conclusion

This $30 billion investment propels the US to hemp dominance, with Colorado as the hub for max ROI.

© 2025 Geodyn Solutions. All rights reserved.