250MW Mobile Power Plants Environmentally Responsible Sustainable Energy Solutions Puerto Rico

PROPOSAL SUMMARY

- One (1) set of power plant including five (5) GE TM2500 mobile Power Plants with a steam turbine.

- The units are trailer mounted modulars, and operational in a few days. The TM2500 are 35 MW capacity each, and will be run as one unit, with the steam turbine running off waste steam in a combined cycle (CC) configuration increasing efficiency and reducing the kwh cost.

- The units are designed to run off multi-fuels, including biodiesel, ethanol, methanol, natural gas, thus reducing the risk of price increases in any one of the potential fuels.

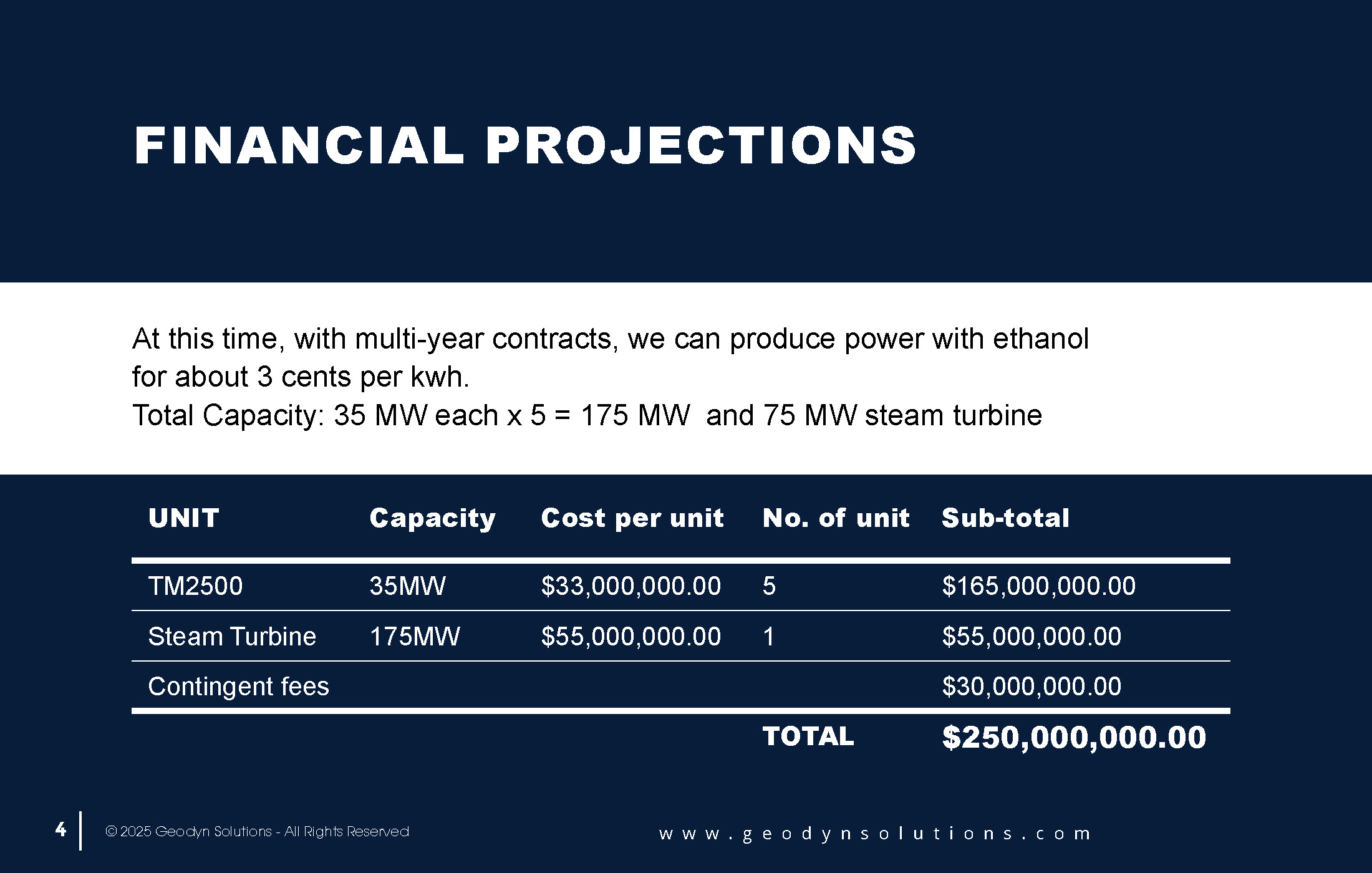

FINANCIAL PROJECTIONS

At this time, with multi-year contracts, we can produce power with ethanol for about 3 cents per kwh.

Total Capacity: 35 MW each x 5 = 175 MW and 75 MW steam turbine.

UNIT | Capacity | Cost per unit | No. of unit | Sub-total |

TM2500 | 35MW | $33,000,000.00 | 5 | $165,000,000.00 |

Steam Turbine | 175MW | $55,000,000.00 | 1 | $55,000,000.00 |

Contingent fees | $30,000,000.00 | |||

TOTAL | $250,000,000.00 | |||

Typical Weights and Dimensions

Approx. Weight (lbs.) | L x W x H (feet) | |

Turbine Trailer 1.2 Without Stinger With Stinger | 90,145 95,139 | 55’ L x 9.8’ W x 13.2’ H 69.6’ L x 9.8’ W x 13.2’ H |

Generator Trailer1.2 Extendable Stinger set to EU Extendable Stinger to US Extendable Stinger set to CAN With Cold Steel Version | 157,380 157,380 157,380 161,822 | 68.6’ L x 9.8’ W x 12.4’ H 76’ L x 9.8’ W x 12.4’ H 84’ L x 9.8’ W x 12.4’ H Dependent on Stinger Setup |

Control House Trailer1.2 | 47,490 | 41.7’ L x 9.2’ W x 14’ H |

Transportation Trailer12.3 | 49,435 | 43.2’ L x 9.8’ W x 13.6’ H |

Air Filter Assembly (including support bracket)2 | 8,674 | 17.8’ L x 8.3’ W x 10.2’ H |

Switchgear | 8,900 | 6’ L x 9.4’ W x 8.1’ H |

Generator 62-170ERT | 84,878 | 19’ L x 8.9’ W x 7.2’ H |

Generator Ventilation | 6,724 | 12.7’ L x 8.4’ W x 9.1’ H |

Control House | 25,463 | 22.8’ L x 8.3’ W x 9.4’ H |

Ventilation Fan Assembly | 4,530 | 10.3’ L x 8.3’ W x 7.9’ H |

Exhoust Stack | 16,323 | 12.2’ L x 8.3’ W x 11’ H |

Crane² | 9,140 | 5.3’ L x 8.3’ W x 8.75’ H |

Generator Air Filters² | 1,600 | 4.4’ L x 8.3’ W x 8.75’ H |

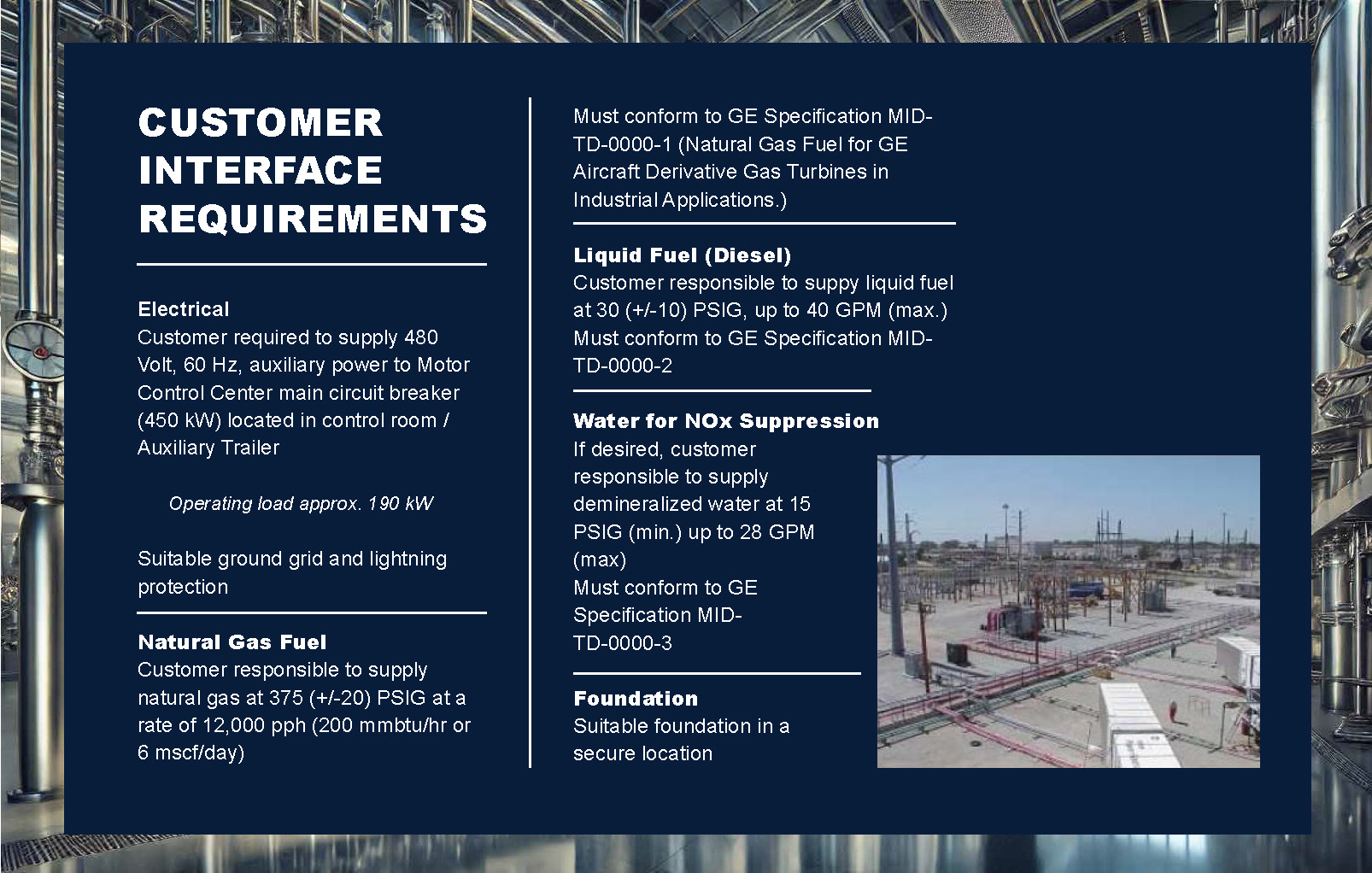

Customer interface requirements

Electrical

Customer required to supply 480 Volt, 60 Hz, auxiliary power to Motor Control Center main circuit breaker (450 kW) located in control room / Auxiliary Trailer

Operating load approx. 190 kW

Suitable ground grid and lightning protection

Natural Gas Fuel

- Customer responsible to supply natural gas at 375 (+/-20) PSIG at a rate of 12,000 pph (200 mmbtu/hr or 6 mscf/day)

- Must conform to GE Specification MID-TD-0000-1 (Natural Gas Fuel for GE Aircraft Derivative Gas Turbines in Industrial Applications.)

Liquid Fuel (Diesel)

- Customer responsible to suppy liquid fuel at 30 (+/-10) PSIG, up to 40 GPM (max.)

- Must conform to GE Specification MID-TD-0000-2

- Water for NOx Suppression

- If desired, customer responsible to supply demineralized water at 15 PSIG (min.) up to 28 GPM (max)

- Must conform to GE Specification MID-TD-0000-3

Foundation

Suitable foundation in a secure location

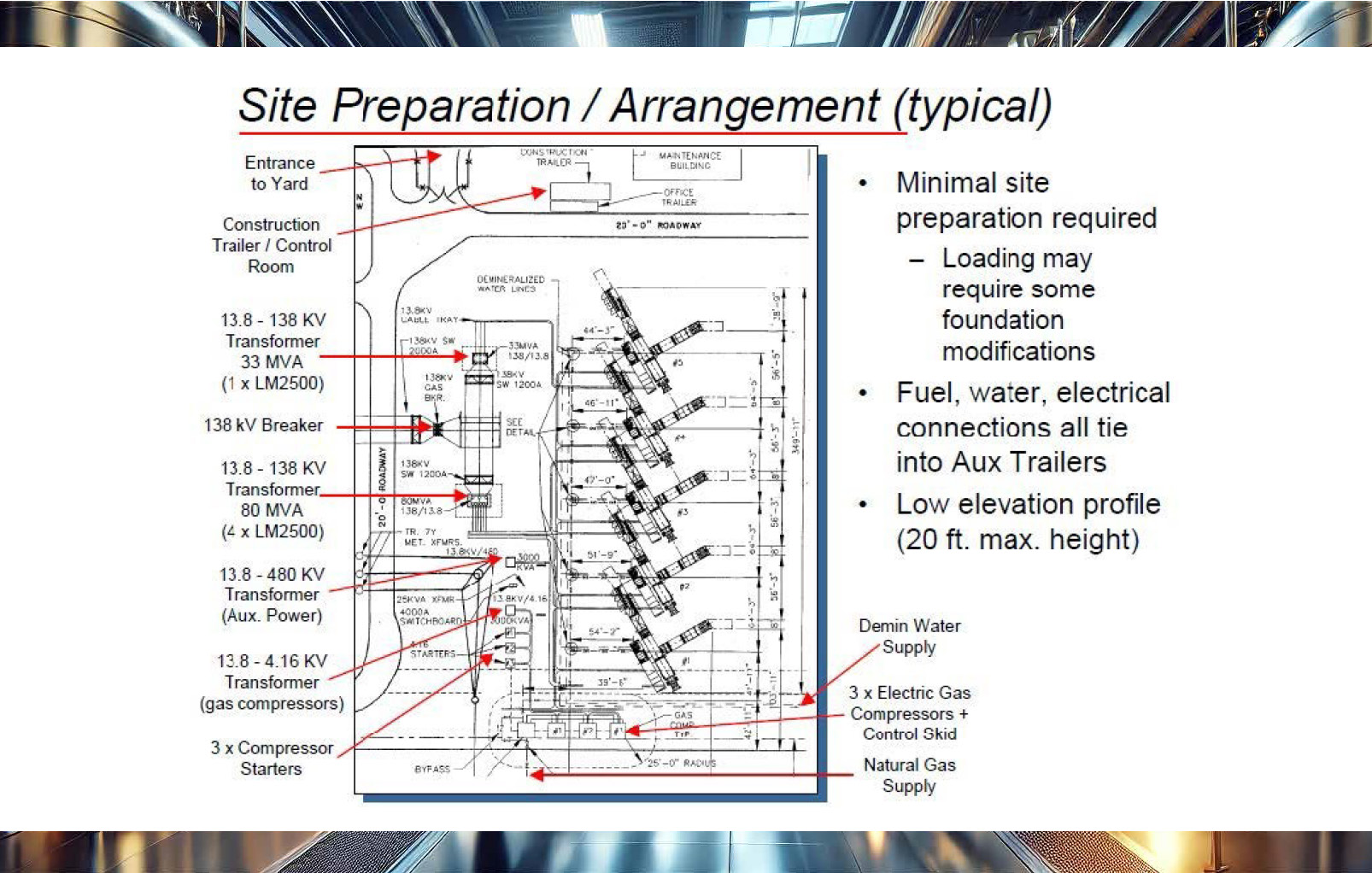

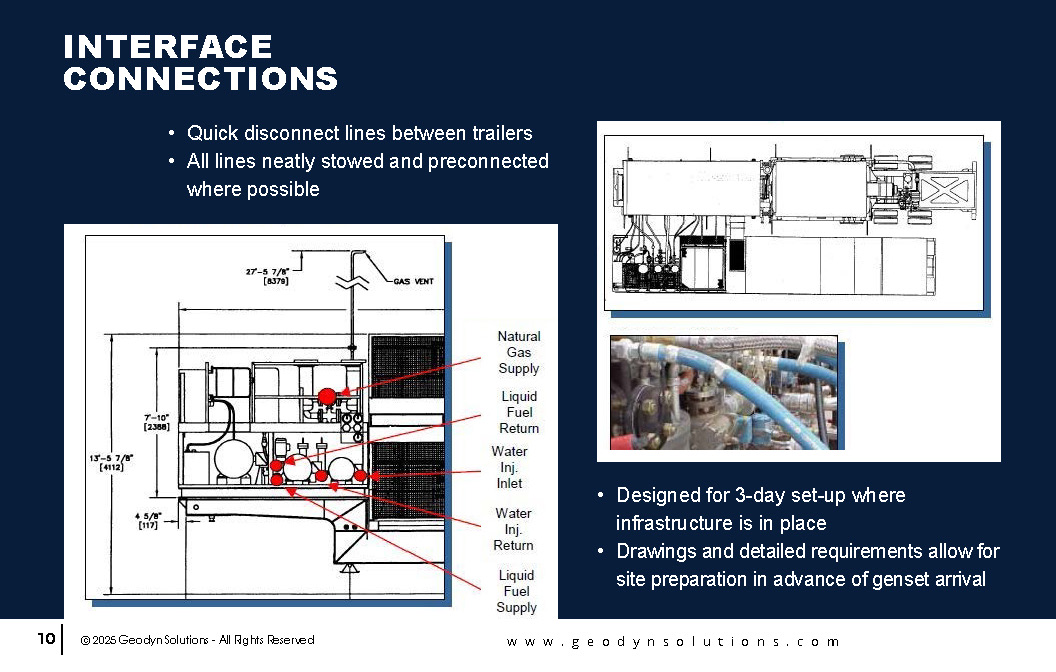

Interface connections

- Quick disconnect lines between trailers

- All lines neatly stowed and preconnected where possible

- Designed for 3-day set-up where infrastructure is in place

- Drawings and detailed requirements allow for site preparation in advance of genset arrival