150 MW Advanced Tire-to-Energy Facility in Puerto Rico

Puerto Rico generates over 4 million waste tires annually, leading to illegal dumping, environmental degradation, and serious health risks. Geodyn Solutions proposes a 150 MW hybrid renewable energy facility that converts these tires into clean, baseload electricity through advanced pyrolysis systems, Heat Recovery Steam Generators (HRSG), and Organic Rankine Cycle (ORC) units. The project will produce electricity at $0.19/kWh, eliminate tire waste, reduce emissions, create long-term jobs, and return over 460% ROI within 12 years. A 25% incidental expense reserve is included to account for inflation, logistics risks, regulatory requirements, and other unforeseen costs—ensuring financial sustainability and execution certainty.

- Project Goals

- Build a 150 MW tire-to-energy plantutilizing pyrolysis, HRSG, and ORC technologies.

- Divert over 4 million tires per year from Puerto Rican landfills and illegal dumps.

- Generate revenue from:

- Electricity sales

- Carbon credits

- Tipping fees

- Recovered steel and carbon black

- Include a 25% cost buffer for unforeseen expenses to ensure financial durability.

- Create long-term green jobs and support the island’s clean energy transition.

- Puerto Rico’s Tire Waste Challenge

- 4M+ scrap tires/yeargenerated with inadequate recycling capacity.

- Dumped tires cause:

- Mosquito breeding grounds (Zika, dengue, chikungunya)

- Tire fires and air pollution

- Leaching of heavy metals and hydrocarbons into soil and groundwater

- Existing programs are reactive and unsustainable—this solution is permanent and revenue-generating.

- Technical Solution

Tire Pyrolysis

- Converts shredded tires into:

- Pyrolysis oil(used as fuel for turbines)

- Syngas(used in gas turbines)

- Recovered steel and carbon blackfor resale

Hybrid Power System

- Gas Turbines: Powered by pyrolysis-derived fuels.

- HRSG: Captures heat from turbines to generate steam.

- ORC Unit: Converts low-temperature residual heat into additional electricity.

- System Output: 150 MW net generation capacity.

- Efficiency: 35–40% thermal-to-electric conversion.

- Site & Infrastructure Requirements

- Land Requirement: 50–60 acres

- Estimated Land Cost: $3M–$5M (based on location)

- Facility Includes:

- Pyrolysis & processing lines

- Gas turbine and HRSG plant

- ORC system

- Material recovery and logistics area

- Green buffer zones for environmental compliance

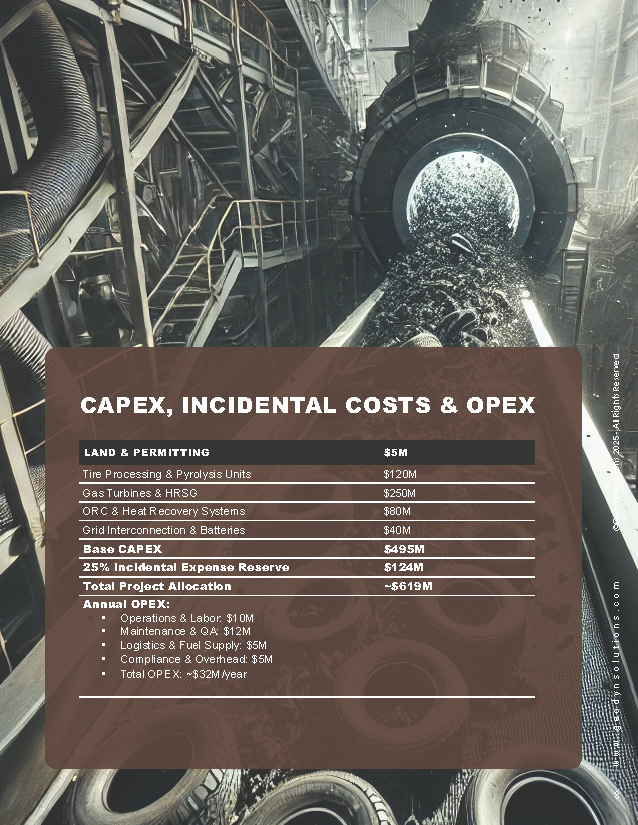

- CAPEX, Incidental Costs & OPEX

Component | Estimated Cost (USD) |

Land & Permitting | $5M |

Tire Processing & Pyrolysis Units | $120M |

Gas Turbines & HRSG | $250M |

ORC & Heat Recovery Systems | $80M |

Grid Interconnection & Batteries | $40M |

Base CAPEX | $495M |

25% Incidental Expense Reserve | $124M |

Total Project Allocation | ~$619M |

Annual OPEX:

- Operations & Labor: $10M

- Maintenance & QA: $12M

- Logistics & Fuel Supply: $5M

- Compliance & Overhead: $5M

- Total OPEX:~$32M/year

- Annual Revenue Streams

Source | Details | Revenue |

Electricity Sales | 150 MW × 8,000 hrs × $0.19/kWh | ~$228M/year |

Tipping Fees | 300,000 tons × $70/ton | ~$21M/year |

Carbon Credits | 400,000 tCO₂e × $30/ton | ~$12M/year |

Material Recovery | Steel, carbon black, ash | ~$3M/year |

Total Annual Revenue | ~$264M/year |

- Financial Performance & ROI (12-Year Projection)

Metric | Value |

Total Project Allocation | ~$619M |

Average Annual Net Income | ~$232M |

Payback Period | ~2.7 years |

12-Year Net Income | ~$2.78B (before tax) |

12-Year ROI | >460% |

Note: Excludes upside from energy price increases, carbon credit inflation, or further efficiency gains.

- Environmental Impact

- Diverts over 4 million tires per yearfrom landfills and illegal dumps.

- Reduces GHG emissions by 400,000 tons CO₂e/year.

- Prevents tire fires and soil/water contamination.

- Reduces disease vectors caused by stagnant water in tire piles.

- Advances Puerto Rico’s goals for resilient infrastructure, waste reduction, and carbon neutrality.

- Economic & Social Benefits

Category | Estimated Jobs |

Tire Collection/Logistics | 150 |

Facility Operations | 100 |

Maintenance/QA | 60 |

Administration/Compliance | 30 |

Local Supply Chain Impact | 300+ |

Total Jobs Created | ~640+ |

- Strong economic stimulus in rural or industrial zones.

- Potential for workforce training and technical partnerships with universities.

- Government Incentives & Carbon Credits

- Eligible for:

- IRA Clean Energy Tax Credits (USA)

- DOE Waste-to-Energy Grants

- FEMA Resilience and Recovery Funds

- Carbon Offset Programs(Verra, Gold Standard, or CORSIA)

- Potential for long-term Power Purchase Agreements (PPAs)with PREPA or private off-takers.

- Implementation Timeline

Phase | Duration |

Permitting & Feasibility | 6–9 months |

Engineering & Procurement | 9–12 months |

Construction & Commissioning | 18–24 months |

Commercial Operation | Year 3 |

ROI Achieved | Year 12 |

- Conclusion

Geodyn Solutions’ 150 MW Advanced Tire-to-Energy Facility presents a breakthrough solution to Puerto Rico’s long-standing tire waste and energy insecurity challenges. With a modern mix of pyrolysis, HRSG, and ORC technologies, this project transforms waste into long-term, reliable power. A built-in 25% incidental expense reserve ensures operational stability and risk mitigation, while the project delivers high-impact economic, environmental, and energy security benefits.

This initiative is financially sound, environmentally critical, and socially responsible—and ready to become a model of circular energy for island nations and developing regions worldwide.